Composite Membrane Engineering Construction: Techniques and Applications

Release time:

Aug 23,2023

1. Introduction

Composite membrane systems have become a critical solution in modern civil engineering, environmental protection, and water resource management. These engineered systems combine multiple layers of geosynthetics (such as geomembranes, geotextiles, and drainage nets) to provide superior performance in containment, reinforcement, and filtration applications. This article details the construction methodology, quality control measures, and key applications of composite membrane engineering projects.

2. Advantages of Composite Membrane Systems

Enhanced Performance: Combines the strengths of different materials (e.g., impermeability + tensile strength + drainage)

Cost Efficiency: Reduces the need for multiple separate layers

Durability: Resistant to punctures, UV degradation, and chemical exposure

Versatility: Adaptable to various engineering challenges (landfills, ponds, tunnels)

Environmental Protection: Effective containment of pollutants and leachate

3. Construction Process

3.1 Site Preparation

Topographic Survey: Detailed mapping of the construction area

Subgrade Preparation:

Removal of sharp objects and vegetation

Compaction to ≥90% of maximum dry density

Achieving proper slope gradients (typically 2-3%)

3.2 Material Selection & Handling

Common Composite Structures:

Geomembrane/Geotextile (GM/GT)

Geomembrane/Drainage Net (GM/DN)

Bentonite Geosynthetic Clay Liner (GCL)

Storage Requirements: Protected from UV exposure, stored on flat surfaces

3.3 Installation Procedures

Unrolling & Positioning:

Deploy materials with minimum 300mm side overlaps

Maintain 1.5% slack to accommodate thermal expansion

Seaming Techniques:

Thermal Fusion: For HDPE membranes (optimal temperature 280-320°C)

Chemical Bonding: For certain polymer combinations

Mechanical Fixing: Using batten strips for temporary positioning

Quality Assurance Testing:

Destructive Testing: Shear and peel tests on sample seams

Non-Destructive Testing: Air lance or vacuum box methods

Electrical Leak Detection: For critical containment applications

3.4 Protection Layer Installation

Geotextile Cushioning: Minimum 300g/m² nonwoven geotextile

Ballast Placement: Even distribution of protective cover materials

Anchoring Systems: Trenches, concrete deadmen, or soil anchors

4. Special Applications

4.1 Landfill Engineering

Base Liner Systems: 1.5mm HDPE + GCL + drainage composite

Cap Systems: Multilayer design with gas collection components

4.2 Water Containment

Reservoir Liners: UV-stabilized composite membranes

Aquaculture Ponds: Flexible membrane systems with protective layers

4.3 Transportation Infrastructure

Tunnel Waterproofing: Composite membranes with drainage boards

Bridge Deck Protection: Polymer-modified bituminous membranes

5. Quality Control Measures

Material Certification: Verification of manufacturer test reports

Field Testing Protocol:

Seam strength testing (every 150m)

Thickness verification (10% of rolls)

Construction Monitoring:

Daily inspection logs

Digital documentation with GPS mapping

6. Maintenance & Long-Term Performance

Inspection Schedule: Biannual visual inspections + annual performance testing

Repair Methods:

Patch installation for minor damages

Section replacement for major failures

Design Life: 30-50 years for properly installed systems

7. Conclusion

Composite membrane engineering represents a sophisticated integration of material science and construction technology. When executed with proper attention to design specifications and installation quality, these systems provide reliable, long-term performance in some of the most demanding engineering applications. The future development of smart membranes with embedded sensors promises to further revolutionize this field.

Key Terminology

Composite Membrane : Engineered multilayer geosynthetic system

Geomembrane : Impermeable polymeric sheet

Geotextile : Permeable fabric layer

Seam Integrity : Strength and continuity of joined sections

Leachate : Contaminated liquid requiring containment

Would you like any particular section expanded with more technical details or case study examples?

News

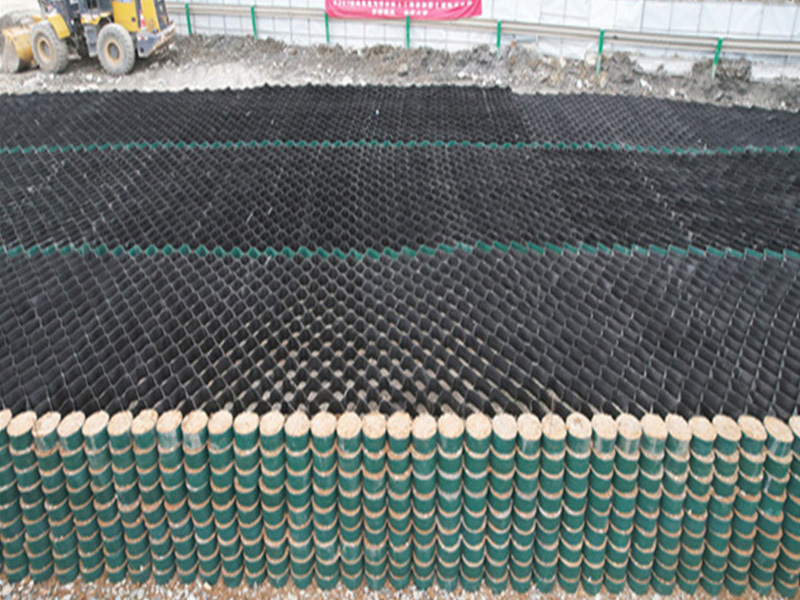

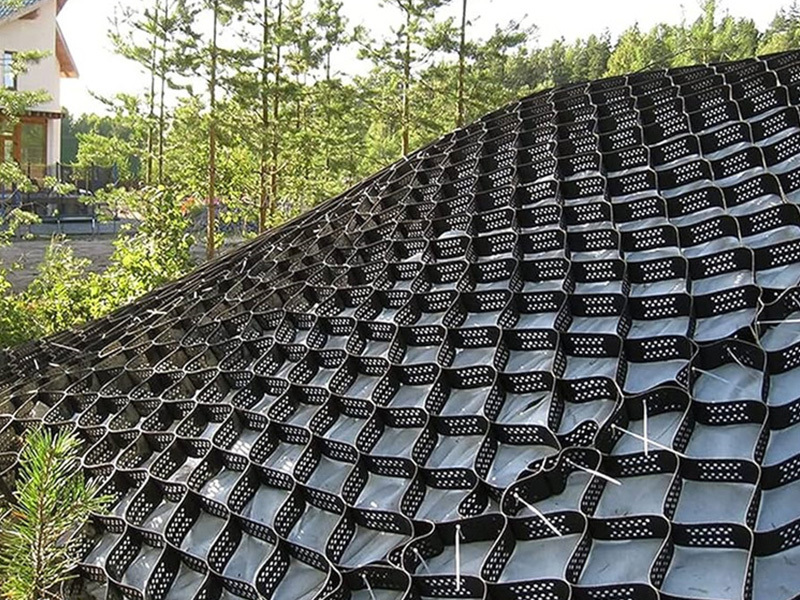

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection

HDPE Geomembrane Waterproofing Construction for Reservoirs

Waterproofing Construction for Reservoirs