Geomembrane Biogas Digester: Construction Techniques and Benefits

Release time:

Sep 08,2023

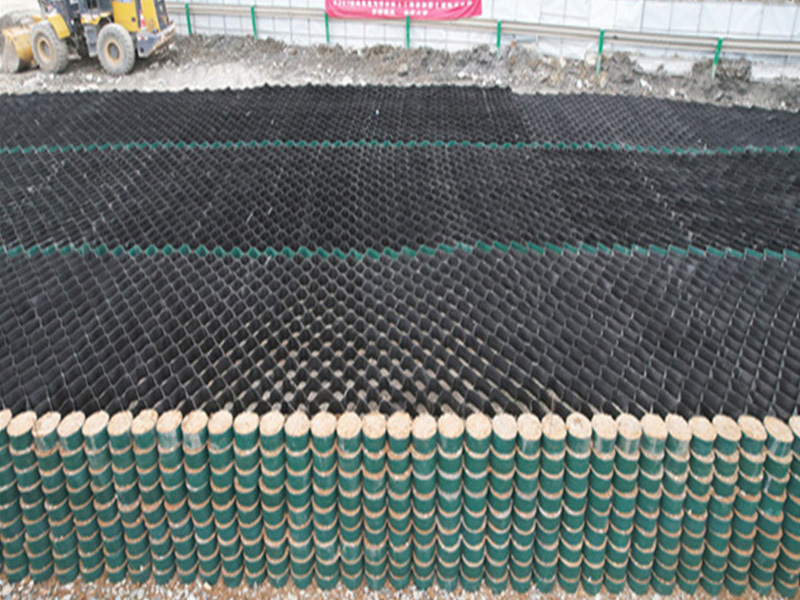

Geomembrane Biogas Digester Construction

A geomembrane biogas digester is an efficient, low-cost anaerobic digestion system that uses a high-density polyethylene (HDPE) or polyvinyl chloride (PVC) geomembrane liner to contain organic waste and capture methane gas for energy production. This technology is widely used in agricultural, industrial, and municipal waste management due to its durability, flexibility, and ease of installation.

2. Advantages of Geomembrane Biogas Digesters

Cost-Effective: Lower construction costs compared to concrete or steel digesters.

Rapid Installation: Can be deployed in days, reducing labor and downtime.

Leak-Proof: Impermeable geomembrane prevents gas and liquid leakage.

Adaptability: Suitable for varying scales (household farms to large industrial plants).

Corrosion Resistance: Withstands harsh chemicals in organic waste.

3. Construction Process

3.1 Site Preparation

Location Selection: Choose a flat, stable area with good drainage.

Excavation: Dig a pit according to design dimensions (typically circular or rectangular).

Subgrade Leveling: Compact the base to avoid punctures and ensure even load distribution.

3.2 Geomembrane Installation

Liner Deployment:

Unroll the geomembrane (typically 1.0–2.5 mm thick HDPE) over the excavated pit.

Ensure sufficient overlap (min. 30 cm) for welding seams.

Welding & Sealing:

Use hot wedge welding or extrusion welding to join geomembrane panels.

Conduct air pressure tests to confirm seam integrity.

Anchoring:

Secure edges in a perimeter trench or with sandbags/ballast to prevent wind uplift.

3.3 Gas & Slurry System Integration

Gas Collection Dome: Install a flexible cover (often made of reinforced geomembrane) with a gas outlet valve.

Inlet/Outlet Pipes: Embed pipes for feeding organic waste (inlet) and discharging digested slurry (outlet).

Pressure Relief Valve: Prevents over-pressurization of the digester.

3.4 Testing & Commissioning

Leak Detection: Perform a spark test or water fill test to ensure no breaches.

Trial Run: Feed a small amount of organic waste to check gas production and system stability.

4. Applications

Agricultural Waste Management (livestock manure, crop residues)

Municipal Organic Waste Treatment

Industrial Effluent Digestion (food processing, breweries)

Renewable Energy Production (cooking fuel, electricity generation)

5. Maintenance & Longevity

Regular Inspections: Check for punctures, seam integrity, and gas leaks.

Slurry Removal: Clear digested material periodically to maintain efficiency.

UV Protection: If exposed, use UV-resistant geomembrane or cover with soil/foam.

Lifespan: Properly installed HDPE geomembranes last 15–20+ years.

6. Conclusion

Geomembrane biogas digesters provide a sustainable and economical solution for organic waste treatment and renewable energy generation. Their modular design and chemical resistance make them ideal for rural and industrial applications alike. With proper installation and maintenance, they offer long-term environmental and economic benefits.

News

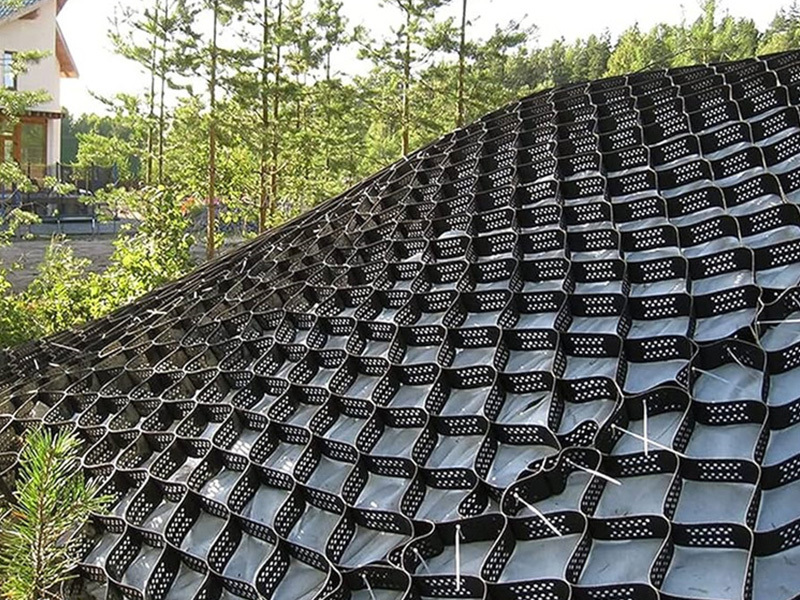

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection

HDPE Geomembrane Waterproofing Construction for Reservoirs

Waterproofing Construction for Reservoirs