Application of Filament Geotextile in Highway Construction

Release time:

May 27,2025

Introduction

Filament geotextile, a type of nonwoven geosynthetic material made from continuous polyester or polypropylene fibers, plays a crucial role in modern highway construction. Its high tensile strength, puncture resistance, and excellent filtration properties make it an ideal solution for subgrade stabilization, separation, drainage, and erosion control. This article explores the key functions, advantages, and construction methods of filament geotextile in highway projects.

Key Functions in Highway Construction

Separation

Filament geotextile prevents the mixing of different soil layers (e.g., subgrade and aggregate base), maintaining structural integrity and prolonging road lifespan.

Example: Placed between soft subsoil and crushed stone to avoid contamination.

Reinforcement

Enhances load-bearing capacity by distributing traffic loads evenly, reducing differential settlement.

Particularly useful in weak subgrade conditions (e.g., marshlands or clay soils).

Filtration & Drainage

Allows water to pass while retaining fine particles, preventing clogging of drainage systems.

Reduces pore water pressure, minimizing frost heave and soil erosion.

Erosion Control

Protects slopes and embankments from water runoff and wind erosion.

Advantages Over Traditional Methods

Cost-Effective: Reduces aggregate thickness requirements, lowering material costs.

Durable: Resistant to UV rays, chemicals, and biological degradation.

Easy Installation: Lightweight and roll-based, enabling rapid deployment.

Construction Best Practices

Subgrade Preparation

Level and compact the soil; remove sharp debris to avoid geotextile damage.

Geotextile Installation

Unroll the fabric longitudinally along the road alignment with 0.3–0.5m overlaps.

Secure edges with staples or backfill immediately to prevent displacement.

Covering & Compaction

Place aggregate/soil layers (min. 150mm thick) on top to avoid puncture during compaction.

Use lightweight machinery initially to prevent fabric distortion.

Case Study: Success in Practice

In a highway project in Jiangsu, China, filament geotextile was used to stabilize a soft clay subgrade. Post-construction monitoring showed a 40% reduction in settlement and no pavement cracking after two years, proving its effectiveness.

Conclusion

Filament geotextile is a versatile and economical solution for highway construction, offering superior separation, reinforcement, and drainage capabilities. Proper installation ensures long-term performance, making it indispensable for sustainable infrastructure development.

Keywords: Filament geotextile, highway construction, soil stabilization, geosynthetics, road reinforcement.

Let me know if you'd like to expand on specific sections (e.g., material specifications, comparative analysis with woven geotextiles)!

News

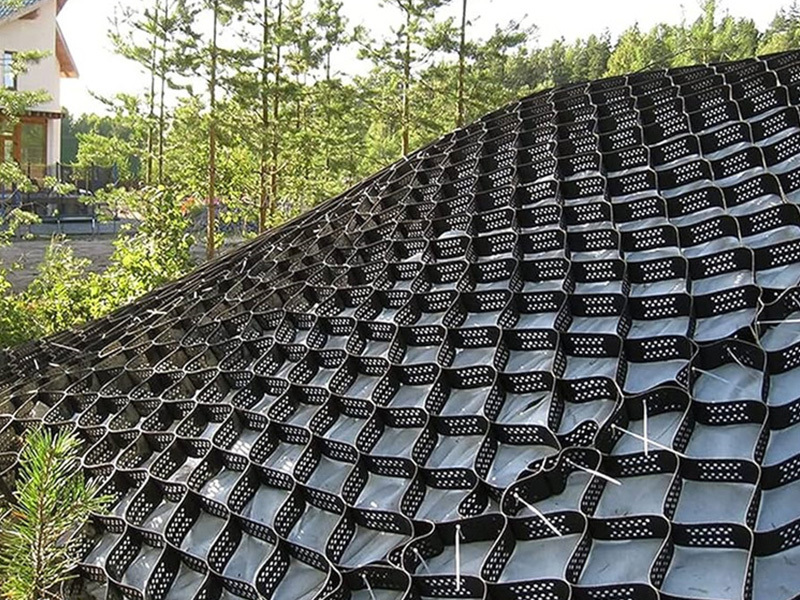

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection