Geotextile Reservoir Anti-Seepage Construction Guide

Release time:

Jul 19,2023

Geotextile Reservoir Anti-Seepage Construction Guide

1. Introduction

Geotextile-based anti-seepage systems provide an economical and effective solution for water containment in reservoirs. This construction method combines geotextile fabrics with impermeable membranes to create durable hydraulic barriers that prevent water loss through seepage while maintaining structural stability.

2. System Components

Primary Layer: Non-woven geotextile (200-500g/m²) for protection and drainage

Barrier Layer: HDPE/LLDPE geomembrane (0.75-2.0mm) as primary water barrier

Ancillary Materials:

Bentonite mats (for secondary containment)

Drainage composites (where required)

UV-protective coatings (for exposed applications)

3. Construction Methodology

3.1 Site Preparation

Subgrade Treatment:

Remove all vegetation and sharp objects

Achieve 95% compaction density

Create smooth transitions (1:3 slope maximum)

Install cutoff trenches at perimeter

Quality Verification:

Conduct sand cone tests for compaction

Verify moisture content (±2% of OMC)

Laser-grade check for surface evenness

3.2 Geotextile Deployment

Roll Placement:

Unroll parallel to slope direction

Maintain 50cm minimum overlap at seams

Allow 2-3% slack for thermal movement

Seaming Techniques:

Needle-Punched: For non-critical applications

Thermal Bonded: For structural seams

Chemical Adhesive: For field repairs

3.3 Geomembrane Installation

Welding Protocol:

Double-track hot wedge seams (20mm width)

Test every 100m with vacuum box (25kPa)

Air channel testing for critical zones

Anchoring System:

Anchor trench dimensions: 1m×1m

Backfill with CLSM (Controlled Low-Strength Material)

3.4 Protection Measures

Armor Layer:

30cm gravel (D50=20mm) for submerged areas

Concrete blocks for wave-impact zones

Vegetative Cover:

Erosion control mats on slopes

Root barriers near membrane

4. Quality Assurance

4.1 Material Testing

Geotextile:

Grab strength ≥800N (ASTM D4632)

Puncture resistance ≥400N (ASTM D4833)

Geomembrane:

Tensile strength ≥25MPa (ASTM D6693)

Tear resistance ≥125N (ASTM D1004)

4.2 Field Testing

Seam Peel Test: 1 test per 150m (min. 30N/mm)

Spark Testing: 100% coverage for exposed seams

Leak Location Survey: Electrical method for final verification

5. Maintenance Protocol

Annual Inspections:

Underwater camera surveys

Water balance calculations

Repair Methods:

Peel-and-stick patches for pinholes

Extrusion welding for seam failures

Sectional replacement for >5% damage

6. Performance Metrics

Seepage Rate: <0.5 l/m²/day (for potable water)

Service Life: 25+ years (submerged)

UV Resistance: 10-15 years (exposed)

7. Case Study Data

Three Gorges Project: 1.2 million m² installed

Lake Remediation (California): 65% seepage reduction

Agricultural Reservoirs (India): 90% water retention improvement

8. Conclusion

Geotextile-based anti-seepage systems offer reservoir engineers a technically advanced yet cost-efficient solution. Proper installation following these protocols ensures long-term water conservation with minimal maintenance requirements. Recent advances in conductive geotextiles now enable real-time integrity monitoring, representing the next evolution in seepage control technology.

Key Advantages:

40-60% cost savings vs traditional concrete

3-5x faster installation

Superior crack-bridging capability

Environmentally neutral materials

For critical projects, consider hybrid systems combining geotextiles with GCLs (Geosynthetic Clay Liners) for redundant protection against leakage.

News

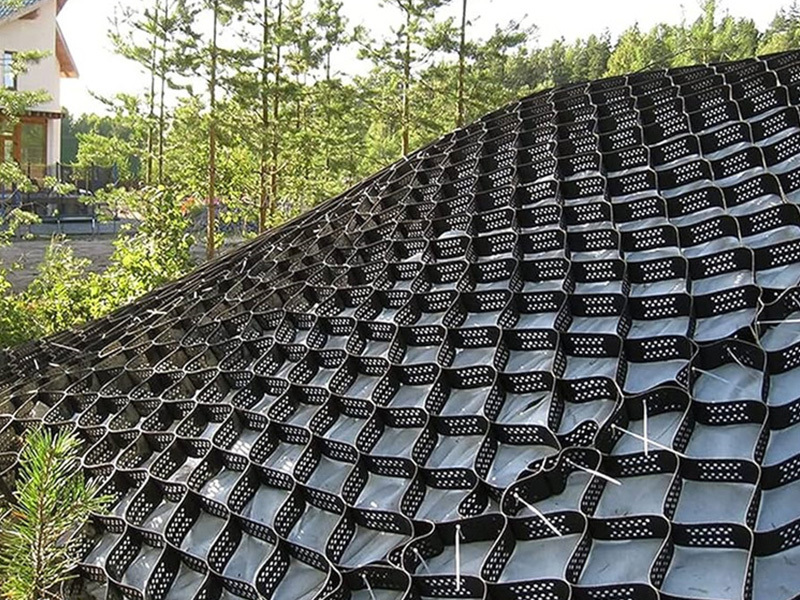

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection

HDPE Geomembrane Waterproofing Construction for Reservoirs

Waterproofing Construction for Reservoirs