Construction of Anti-Seepage Geomembrane for Dams

Release time:

Apr 21,2025

Site Preparation

Clean and level the dam surface, removing sharp objects or debris.

Compact the subgrade to ensure a smooth, stable base.

Geomembrane Installation

Unroll the geomembrane (e.g., HDPE, LDPE, or PVC) over the prepared surface.

Weld adjacent sheets using thermal fusion welding or extrusion welding to ensure seamless joints.

Perform non-destructive testing (e.g., air pressure or vacuum tests) to verify weld integrity.

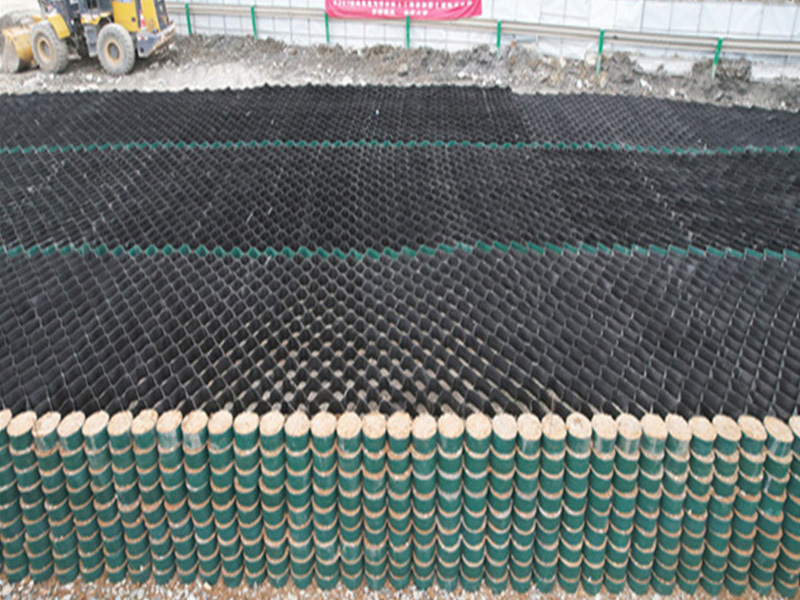

Anchoring & Protection

Secure the geomembrane edges in anchor trenches or with ballast (e.g., gravel or concrete blocks).

Cover with a protective layer (e.g., geotextile or soil) to prevent UV degradation and mechanical damage.

Drainage Integration

Install drainage pipes/geocomposites beneath or above the geomembrane to manage seepage water.

Inspection & Maintenance

Conduct leak detection surveys (e.g., electrical methods) post-installation.

Regularly inspect for punctures or displacements during service life.

Key Terms:

Geomembrane: An impermeable synthetic liner (e.g., HDPE) used for fluid containment.

Anti-seepage: Designed to prevent water leakage in hydraulic structures.

Thermal Fusion Welding: A heat-based method to join geomembrane sheets.

Let me know if you need additional details (e.g., material specifications or ASTM standards)!

News

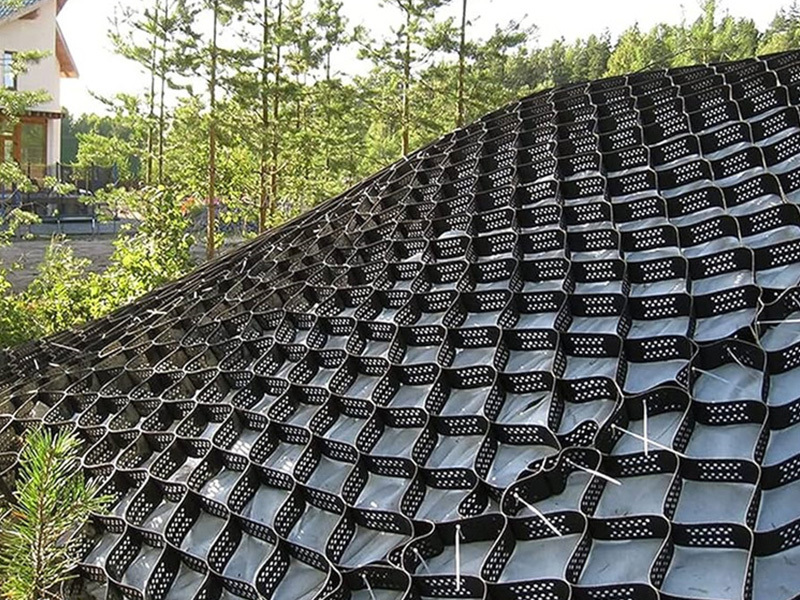

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection