HDPE Geomembrane Waterproofing Construction for Reservoirs

Release time:

Jan 13,2025

Waterproofing Construction for Reservoirs

HDPE (High-Density Polyethylene) geomembranes are widely used in reservoir waterproofing due to their excellent chemical resistance, UV stability, and low permeability. Below are the key construction steps and technical requirements:

1. Pre-Construction Preparation

1.1 Subgrade Treatment

Cleaning & Leveling: Remove sharp objects (roots, stones, etc.), ensuring the surface is smooth (max. undulation ≤ 2 cm).

Compaction: Achieve ≥ 90% compaction to prevent settlement.

Drainage System: Install gravel drains or perforated pipes to relieve hydrostatic pressure.

Slope Design: Recommended slope ≤ 1:1.5 (V:H); steeper slopes require terraces or anchor trenches.

1.2 Material Selection

Geomembrane Thickness: Typically 0.5–3.0 mm (1.0–2.0 mm for most reservoirs).

Protective Layer: Non-woven geotextile (300–600 g/m²) to prevent puncture.

Welding Equipment: Dual-hot wedge welder for seams, extrusion welder for repairs.

2. Geomembrane Installation

2.1 Laying Process

Unrolling Method: Deploy rolls downhill, overlapping seams (min. 10 cm).

Relaxation Allowance: Leave ~5% slack for thermal expansion/contraction.

Anchoring: Secure edges in anchor trenches (min. depth 0.5 m) or with ballast.

2.2 Seam Welding

Thermal Welding:

Temperature: 250–400°C (adjust based on ambient conditions).

Speed: 1.5–3.0 m/min for consistent fusion.

Test Seams: Perform peel/shear tests (ASTM D6392).

2.3 Quality Control

Air Pressure Test: Apply 200 kPa to welded seams; pressure drop ≤ 20% in 5 min.

Spark Test: For detecting pinholes in conductive geomembranes.

3. Post-Installation Measures

Protection Layer: Cover with 30–50 cm soil or sand to prevent UV degradation.

Inspection: Regular checks for leaks (e.g., electrical leak detection).

Vegetation Control: Avoid deep-rooted plants near the geomembrane.

Key Standards

ASTM D7467: HDPE geomembrane material properties.

GRI GM13: Installation guidelines.

ISO 9001: Quality management in welding.

This method ensures a durable, impermeable barrier for reservoir waterproofing. Proper execution minimizes leakage risks and extends service life (>50 years).

News

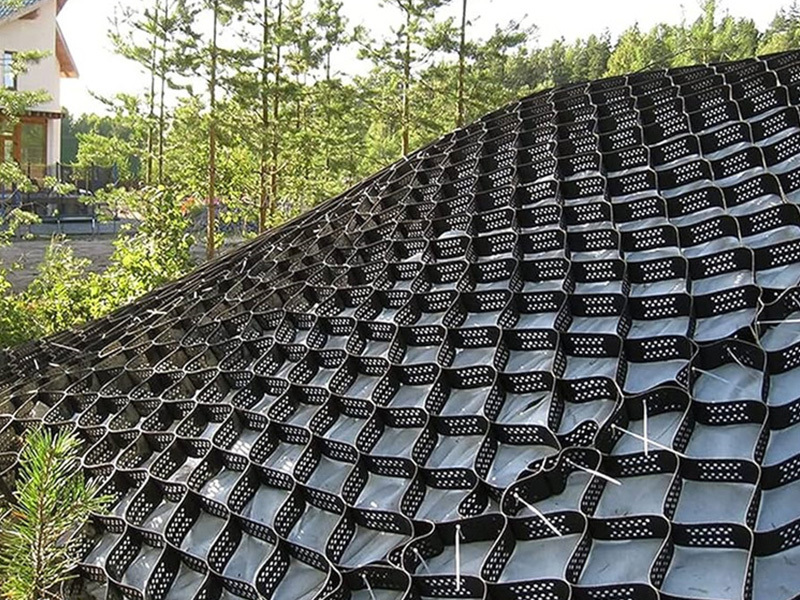

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection