The Application of Geomembranes in Tailings Management

Release time:

Dec 23,2024

Introduction

Tailings, the waste materials left after mineral processing, pose significant environmental and safety challenges. Improper management can lead to contamination of soil, groundwater, and surface water. Geomembranes—impermeable synthetic liners made from materials such as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC)—play a critical role in modern tailings storage facilities (TSFs). They provide a reliable barrier to prevent leachate migration, enhance structural stability, and ensure regulatory compliance.

Key Functions of Geomembranes in Tailings Management

Containment of Hazardous Materials

Prevent leaching of heavy metals, acids, and other toxic substances into the surrounding environment.

Reduce the risk of groundwater contamination.

Seepage Control

Minimize fluid loss from tailings ponds, improving water management and reducing the need for additional water sourcing.

Enhance the efficiency of hydraulic containment systems.

Structural Stability

Provide a stable base for tailings deposition, reducing the risk of slope failure or erosion.

Work in conjunction with geotextiles and drainage layers to improve long-term performance.

Regulatory Compliance

Help mining operations meet environmental protection standards set by agencies such as the EPA, ICMM, and local regulations.

Design and Installation Considerations

1. Material Selection

HDPE: Highly durable, chemical-resistant, and suitable for long-term applications.

LLDPE: More flexible than HDPE, ideal for uneven surfaces or areas requiring elongation.

PVC: Cost-effective for short- to medium-term projects but less resistant to UV and chemicals.

2. Liner System Configuration

Single-Liner Systems: Used in low-risk environments where minimal leakage is acceptable.

Composite Liners: Combine geomembranes with compacted clay or geosynthetic clay liners (GCLs) for enhanced impermeability.

Double-Liner Systems: Include leak detection layers for high-risk TSFs, ensuring early warning of breaches.

3. Installation Process

Subgrade Preparation: Level and compact the foundation to avoid punctures.

Welding/Seaming: Thermally fuse geomembrane panels to ensure a continuous, leak-proof barrier.

Anchoring & Covering: Secure edges with trenches or anchor trenches and protect with soil or geotextile coverings.

4. Quality Assurance & Testing

Conduct spark testing or air lance testing to detect seam defects.

Perform destructive shear and peel tests on sample welds.

Implement regular inspections for tears, UV degradation, or chemical wear.

Challenges and Mitigation Strategies

Puncture Resistance

Use thicker geomembranes (1.5–2.5 mm) or protective geotextiles in high-stress areas.

Chemical Compatibility

Select resins with additives to resist oxidation, acidic/alkaline tailings, or hydrocarbon exposure.

Long-Term Durability

Incorporate UV-stabilized geomembranes for exposed applications.

Monitor for stress cracking in HDPE liners over time.

Case Studies & Innovations

Chilean Copper Mines: Use HDPE geomembranes to prevent acid mine drainage (AMD) in arid climates.

Canadian Oil Sands: Employ double-liner systems with leak detection for oil sands tailings.

Advanced Monitoring: IoT-enabled sensors embedded in liners to track strain and leakage in real time.

Conclusion

Geomembranes are indispensable in modern tailings management, offering environmental protection, regulatory compliance, and operational efficiency. Proper material selection, installation, and maintenance are crucial to maximizing their lifespan and performance. As mining operations face stricter environmental standards, geomembrane technology continues to evolve with stronger, smarter, and more sustainable solutions.

News

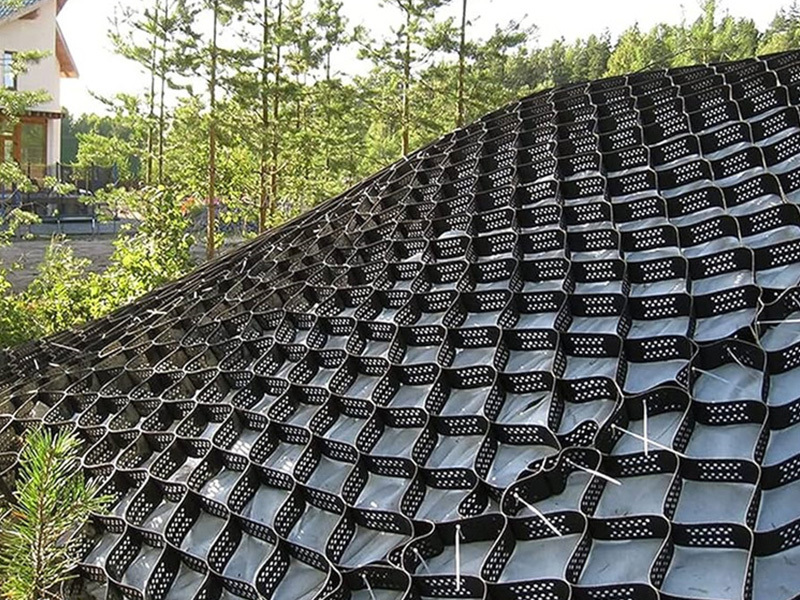

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection