Geocell Reinforcement for Muddy Road Construction

Release time:

Nov 12,2024

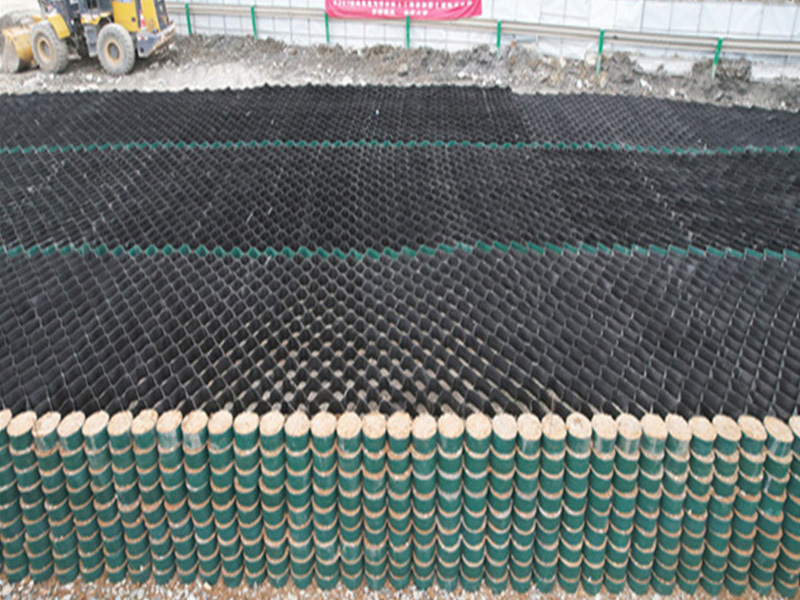

Construction of Geocell

Introduction

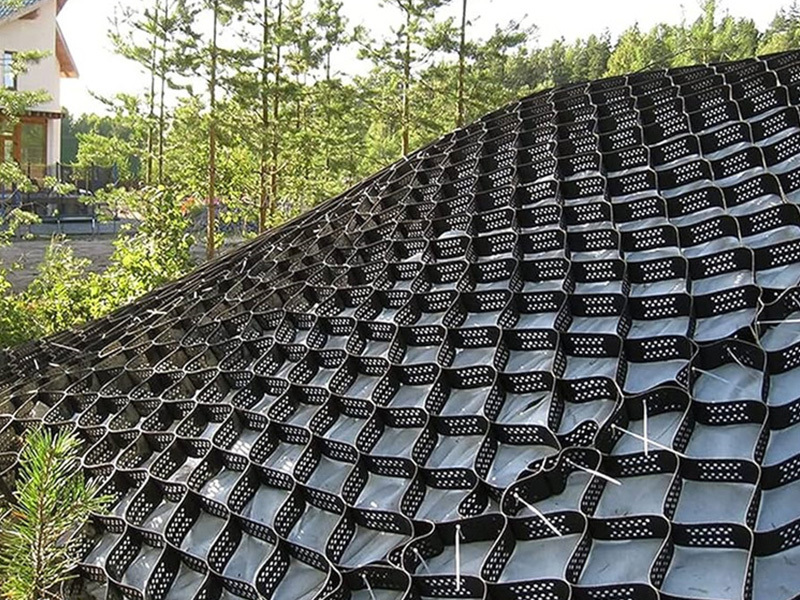

Geocell-reinforced muddy road construction is an effective solution for improving the load-bearing capacity and stability of soft or waterlogged ground. Geocells, three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other polymeric materials, confine and stabilize infill materials such as gravel, sand, or soil. This technique is widely used in temporary access roads, military pathways, and low-volume rural roads where conventional paving methods are impractical.

Advantages of Geocell Reinforcement

Enhanced Load Distribution – Geocells distribute vertical loads over a wider area, reducing rutting and deformation.

Improved Drainage – The cellular structure allows for better water drainage, preventing water accumulation and softening of the subgrade.

Reduced Material Usage – Less infill material is required compared to traditional methods, lowering costs.

Rapid Deployment – Geocells can be installed quickly, making them ideal for emergency or temporary road projects.

Construction Steps

1. Site Preparation

Remove debris, vegetation, and loose soil from the muddy surface.

Level the ground as much as possible to ensure uniform load distribution.

If necessary, install a geotextile layer to prevent mixing of subgrade soil with the infill material.

2. Geocell Installation

Unfold the geocell panels and anchor them to the ground using stakes or pins.

Ensure proper interlocking between adjacent panels to maintain structural integrity.

Expand the geocells to their full height and secure them firmly.

3. Infill Placement

Fill the geocell compartments with granular material (e.g., crushed stone, gravel, or compacted soil).

Compact the infill in layers to achieve optimal density and prevent settling.

Ensure that the infill material slightly overfills the cells to account for future compaction under traffic.

4. Surface Finishing

Grade the surface to the desired profile for proper drainage.

Apply a wearing course (if needed) using finer aggregates or a light asphalt seal for improved durability.

5. Quality Control & Maintenance

Conduct plate load tests to verify bearing capacity.

Regularly inspect for deformation or infill loss, especially after heavy rainfall.

Replenish infill material as needed to maintain road performance.

Conclusion

Geocell reinforcement provides a cost-effective and sustainable solution for constructing stable road surfaces over muddy or weak subgrades. By improving load distribution and reducing material usage, this method ensures long-term performance even in challenging conditions. Proper installation and maintenance are key to maximizing the benefits of geocell-reinforced roads.

News

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection