Construction of Geomembrane Tailings Storage Facilities

Release time:

Jul 01,2025

Introduction

Geomembranes are widely used in tailings management to prevent environmental contamination by creating impermeable barriers that contain mine waste. Made from materials such as HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), or PVC (Polyvinyl Chloride), geomembranes ensure safe storage and reduce the risk of leachate seepage into soil and groundwater. This article outlines the key steps in constructing a geomembrane-lined tailings storage facility (TSF).

Materials and Tools Required

Geomembrane (HDPE, LLDPE, or PVC) – Selected based on chemical resistance and durability.

Geotextile cushion layer – Protects the geomembrane from punctures.

Drainage system – Pipes and gravel layers to manage seepage and gas venting.

Anchoring system – Trenches, bolts, or ballast to secure the geomembrane.

Welding equipment – Hot wedge or extrusion welders for seam sealing.

Leak detection system (optional) – Sensors or electrical methods to monitor integrity.

Construction Steps

1. Site Preparation

Excavation & Grading: Level the ground to remove sharp rocks and debris.

Compaction: Ensure a stable, well-compacted subgrade to prevent settling.

Slope stability: Design side slopes (typically 3H:1V or 4H:1V) to prevent slippage.

2. Installation of Protective Layers

Lay a geotextile cushion (if required) to protect the geomembrane from punctures.

Install a drainage layer (gravel or geocomposite) to manage any seepage.

3. Geomembrane Deployment

Unroll the geomembrane, allowing sufficient overlap (min. 30 cm) for welding.

Smooth out wrinkles to ensure proper fitting and stress distribution.

Secure edges in anchor trenches or with mechanical fasteners.

4. Seam Welding & Quality Control

Use hot wedge welding (for HDPE/LLDPE) or extrusion welding (for repairs).

Conduct air pressure or vacuum tests to check seam integrity.

Perform destructive shear/peel tests on sample seams for quality assurance.

5. Leachate Collection & Gas Venting

Install perforated pipes at the base for leachate drainage.

Include gas vents if tailings produce methane or other gases.

6. Cover System (Optional)

Depending on regulations, a soil or geosynthetic cover may be added to minimize erosion and UV degradation.

Advantages of Geomembrane-Lined Tailings Storage

Environmental protection: Prevents toxic seepage into groundwater.

Cost-effective: Lower installation costs compared to concrete or clay liners.

Longevity: Resistant to chemicals, UV, and mechanical stress.

Flexibility: Adaptable to various terrains and tailings volumes.

Conclusion

Using geomembranes in tailings storage facilities is a proven method to enhance environmental safety and regulatory compliance. Proper installation, welding, and quality control are essential for long-term performance. By following these construction steps, mining operations can effectively manage tailings while minimizing ecological risks.

Would you like additional details on specific aspects such as welding techniques or regulatory compliance?

News

Application of Geotextiles in Tunnel Anti-Seepage Construction

Geotextiles are widely used in tunnel engineering for their excellent anti-seepage, filtration, and drainage properties.

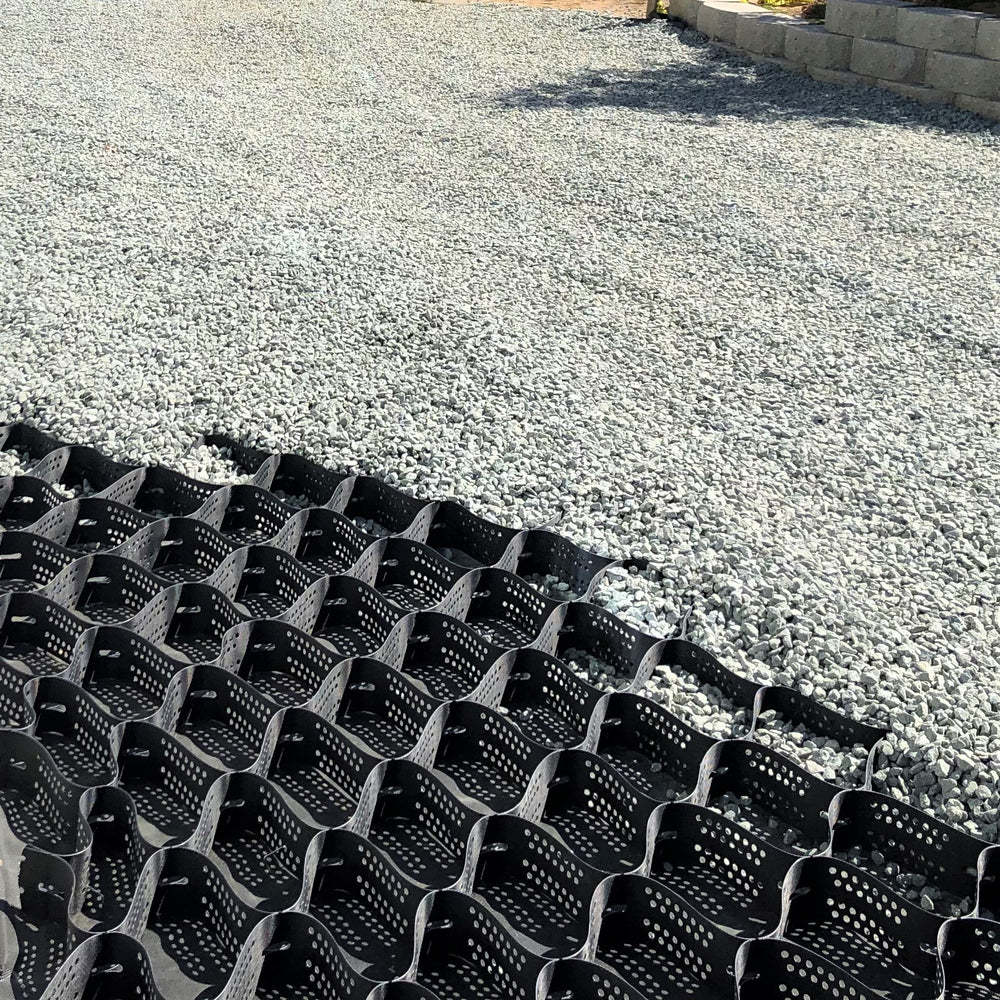

Construction of Geocell Farms: A Step-by-Step Guide

Geocells (also known as cellular confinement systems) are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other polymeric materials. They are widely used in agriculture to improve soil stability, prevent erosion, and enhance crop growth by reinforcing the ground.

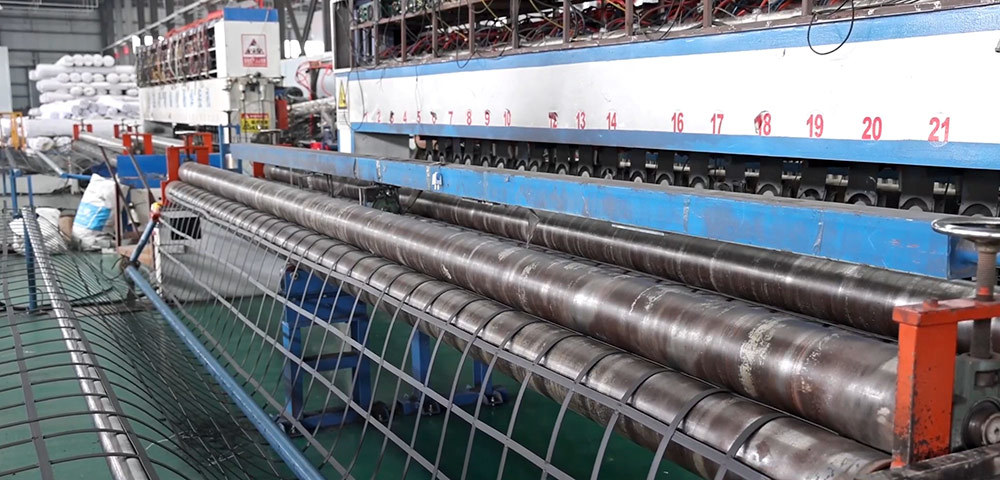

Construction Technology of Geogrid-Reinforced Highway

Geogrid-reinforced highways are an effective solution to improve road stability, reduce settlement, and extend service life. Geogrids, typically made from high-strength polymers such as polyester or fiberglass, are widely used in subgrade reinforcement, slope protection, and pavement structure enhancement.