Construction Technology of Geogrid-Reinforced Highway

Release time:

Jul 16,2025

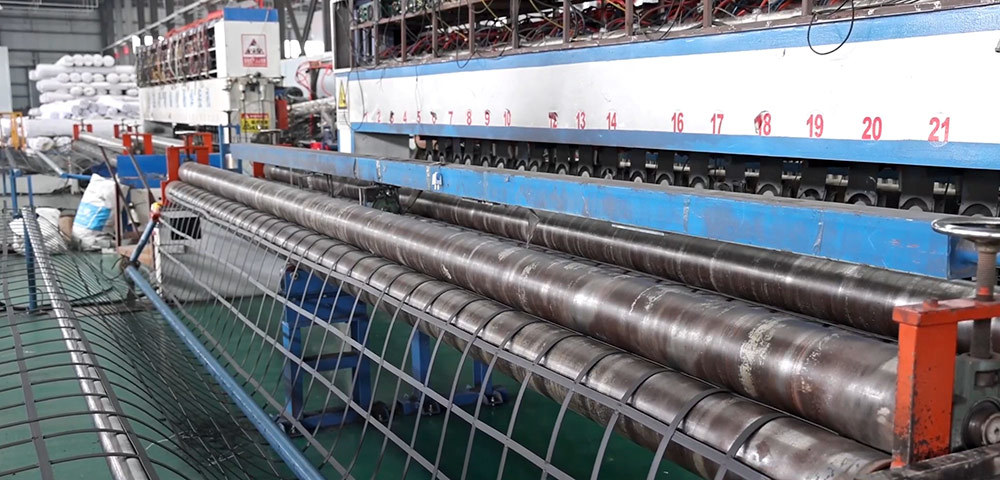

Geogrid-reinforced highways are an effective solution to improve road stability, reduce settlement, and extend service life. Geogrids, typically made from high-strength polymers such as polyester or fiberglass, are widely used in subgrade reinforcement, slope protection, and pavement structure enhancement.

1. Introduction

Geogrid-reinforced highways are an effective solution to improve road stability, reduce settlement, and extend service life. Geogrids, typically made from high-strength polymers such as polyester or fiberglass, are widely used in subgrade reinforcement, slope protection, and pavement structure enhancement. This article outlines the construction process, key technical points, and quality control measures for geogrid-reinforced highway projects.

2. Construction Process

2.1 Preparation

Material Inspection: Ensure the geogrid meets design requirements (tensile strength, elongation, mesh size, etc.).

Subgrade Preparation: Level and compact the subgrade to the required density (≥90% compaction). Remove sharp debris to prevent damage to the geogrid.

Survey & Marking: Mark the laying area according to design drawings.

2.2 Geogrid Laying

Manual Unrolling: Unroll the geogrid along the road alignment, ensuring proper overlap (typically 10–15 cm for longitudinal joints and 20–30 cm for transverse joints).

Direction Alignment: The high-strength direction (main load-bearing axis) should be perpendicular to the road centerline.

Tensioning & Fixation: Use U-shaped nails or sandbags to temporarily fix the geogrid, preventing displacement during backfilling.

2.3 Backfilling & Compaction

Initial Layer (Protective Layer): Spread a 15–20 cm layer of fine-grained soil or sand over the geogrid and lightly compact (avoid heavy machinery directly on the geogrid).

Subsequent Layers: Proceed with standard fill material (gravel, crushed stone) in layers (20–30 cm per layer), compacting to ≥95% density.

2.4 Pavement Construction

After completing the reinforced subgrade, proceed with standard pavement layers (base, binder, and surface courses) as per design specifications.

3. Key Technical Points

Avoid Wrinkles & Folds: Ensure the geogrid lies flat to prevent stress concentration.

Minimize Exposure: Reduce UV exposure time (polyester geogrids degrade under prolonged sunlight).

Seam Connection: Use binding bars or stitching for overlapping sections to ensure continuity.

Slope Reinforcement: For embankments, lay geogrids along the slope with proper anchoring.

4. Quality Control

In-Process Inspection: Check geogrid integrity, overlap width, and backfill compaction.

Post-Construction Testing: Conduct plate load tests or CBR tests to verify reinforcement effectiveness.

5. Conclusion

Geogrid reinforcement enhances highway load-bearing capacity and reduces long-term maintenance costs. Proper construction techniques and strict quality control are essential for optimal performance. Future developments may include smart geogrids with real-time monitoring capabilities for improved durability assessment.

This article provides a general guideline; specific projects should follow detailed design and local regulatory requirements.

News

Application of Geotextiles in Tunnel Anti-Seepage Construction

Geotextiles are widely used in tunnel engineering for their excellent anti-seepage, filtration, and drainage properties.

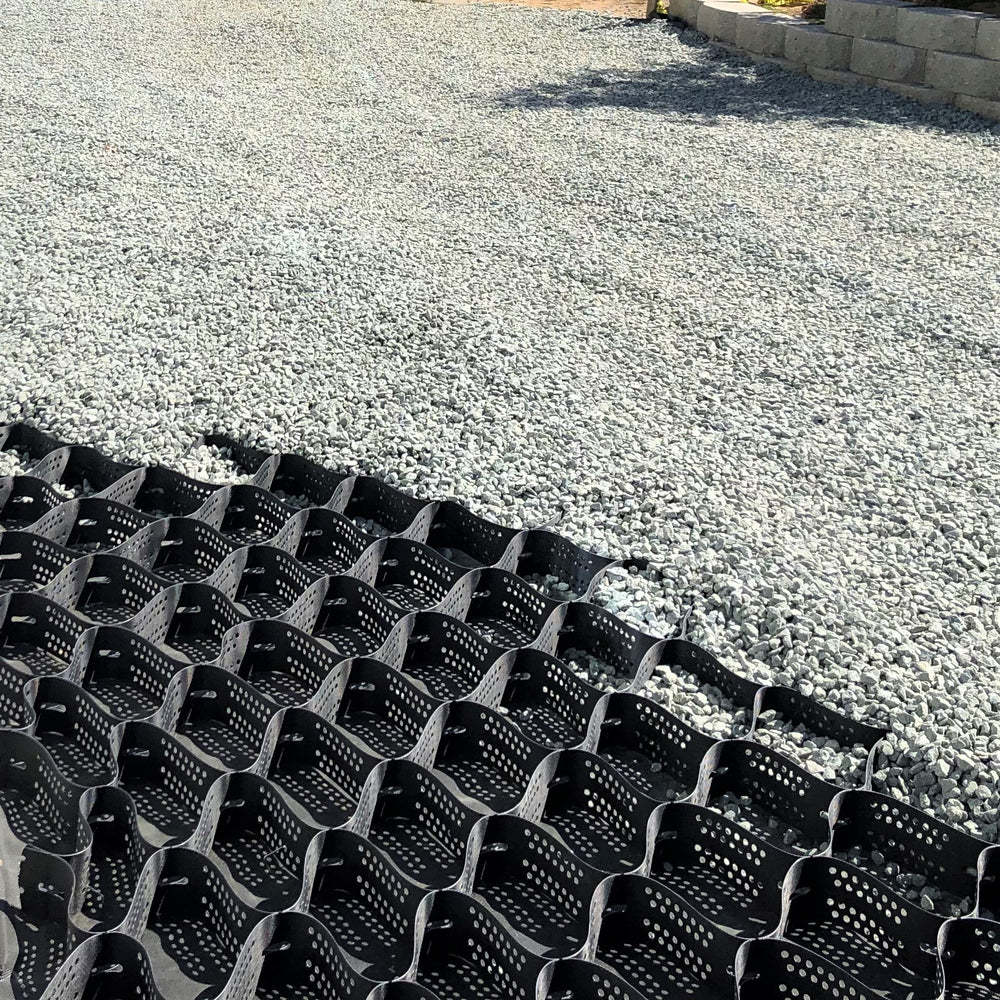

Construction of Geocell Farms: A Step-by-Step Guide

Geocells (also known as cellular confinement systems) are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other polymeric materials. They are widely used in agriculture to improve soil stability, prevent erosion, and enhance crop growth by reinforcing the ground.

Construction Technology of Geogrid-Reinforced Highway

Geogrid-reinforced highways are an effective solution to improve road stability, reduce settlement, and extend service life. Geogrids, typically made from high-strength polymers such as polyester or fiberglass, are widely used in subgrade reinforcement, slope protection, and pavement structure enhancement.