Geotextile Construction for Tunnel Waterproofing and Drainage

Release time:

Sep 02,2025

Abstract:

The application of geotextiles in modern tunnel engineering is a critical component of composite lining systems, primarily serving the functions of drainage, protection, and waterproofing. This article outlines the key construction procedures, material considerations, and best practices for the effective installation of geotextiles in tunnel environments to ensure long-term structural integrity and waterproofing performance.

1. Introduction

Tunnels are inherently vulnerable to water infiltration, which can lead to deterioration of the concrete lining, corrosion of reinforcement, and overall reduction in service life. A geotextile layer, used in conjunction with a waterproofing membrane (typically a PVC or HDPE sheet), forms a primary defense mechanism. The geotextile acts as a drainage medium and a protective cushion, channeling seepage water to drainage pipes while safeguarding the delicate waterproofing membrane from puncture by the rough excavated rock or primary support surface.

2. Material Selection

The choice of geotextile is paramount. For tunnel applications, a non-woven, needle-punched geotextile is almost exclusively used due to its excellent permeability, tensile strength, and puncture resistance.

Material: Polypropylene or polyester.

Weight/Thickness: Typically ranges from 300 to 500 g/m², selected based on the aggressiveness of the substrate and hydrostatic pressure.

Key Properties:

High Permittivity: Allows water to flow freely through its plane.

Puncture Resistance: Withstands contact with sharp rock edges.

Tensile Strength: Resists tearing during handling and installation.

Chemical Inertness: Resists degradation from chemicals present in groundwater.

3. Key Construction Steps

Step 1: Surface Preparation

The initial shotcrete (primary lining) surface must be prepared to provide a sound base. This involves:

Smoothing: Removing any sharp protrusions, rock edges, or rebar ends that could puncture the geotextile or membrane. This is often done by grinding.

Cleaning: Thoroughly removing dust, debris, loose material, and free water. A clean, dry surface is essential for proper adhesion of the subsequent membrane.

Step 2: Installation of Drainage Pipes

Prefabricated drainage strips or pipes (often HDPE) are installed along the tunnel perimeter, typically at the springline and crown, to collect incoming water.

The geotextile will later be wrapped around these pipes to ensure all water transmitted through the fabric is efficiently channeled into the drainage system.

Step 3: Geotextile Installation

The geotextile is supplied in rolls. Installation proceeds from the tunnel invert upwards towards the crown.

The material is unrolled and pressed against the prepared shotcrete surface.

Fastening: The geotextile is secured using specialized plastic fixation plates and rock bolts/nails. The plates have a broad head to distribute the load and prevent tearing.

A typical fixing pattern is a grid of 1.0m x 1.0m on the walls and 0.8m x 0.8m on the crown, adjusted as per design specifications.

Overlapping: Adjacent rolls must overlap by a minimum of 100mm. For critical applications, seams may be stitched or heat-sealed to ensure continuity, though overlapping is often sufficient for drainage functions.

Step 4: Installation of Waterproofing Membrane

Once the geotextile layer is fully installed, the waterproofing membrane is applied on top of it.

The membrane is often heat-welded to the same plastic fixation plates used for the geotextile, creating a continuous, anchored waterproofing barrier. The geotextile beneath prevents the membrane from being pressed directly onto the abrasive shotcrete.

Step 5: Placement of Secondary Lining

The final structural concrete lining (secondary lining) is cast in situ against the waterproofing membrane. The geotextile layer ensures that any minor water ingress is kept away from the final lining, directing it harmlessly to the drainage system.

4. Quality Control and Inspection

Rigorous inspection is crucial throughout the process:

Material Certification: Verify that geotextile properties meet project specifications.

Surface Inspection: Check for sharp protrusions and cleanliness before installation.

Seam Integrity: Ensure all overlaps are sufficient and secure.

Fixation: Confirm the spacing and tightness of all fixing points.

Post-Installation Check: Inspect the entire installed system for tears, sagging, or damage before placing the membrane and concrete.

5. Conclusion

The correct installation of geotextiles is a fundamental step in constructing durable, watertight tunnels. It is a system that works in tandem with drainage and waterproofing elements. By meticulously preparing the substrate, carefully selecting the appropriate material, and adhering to precise installation techniques, engineers can create a highly effective drainage plane that protects the primary waterproofing barrier and ensures the long-term performance and safety of the tunnel structure.

News

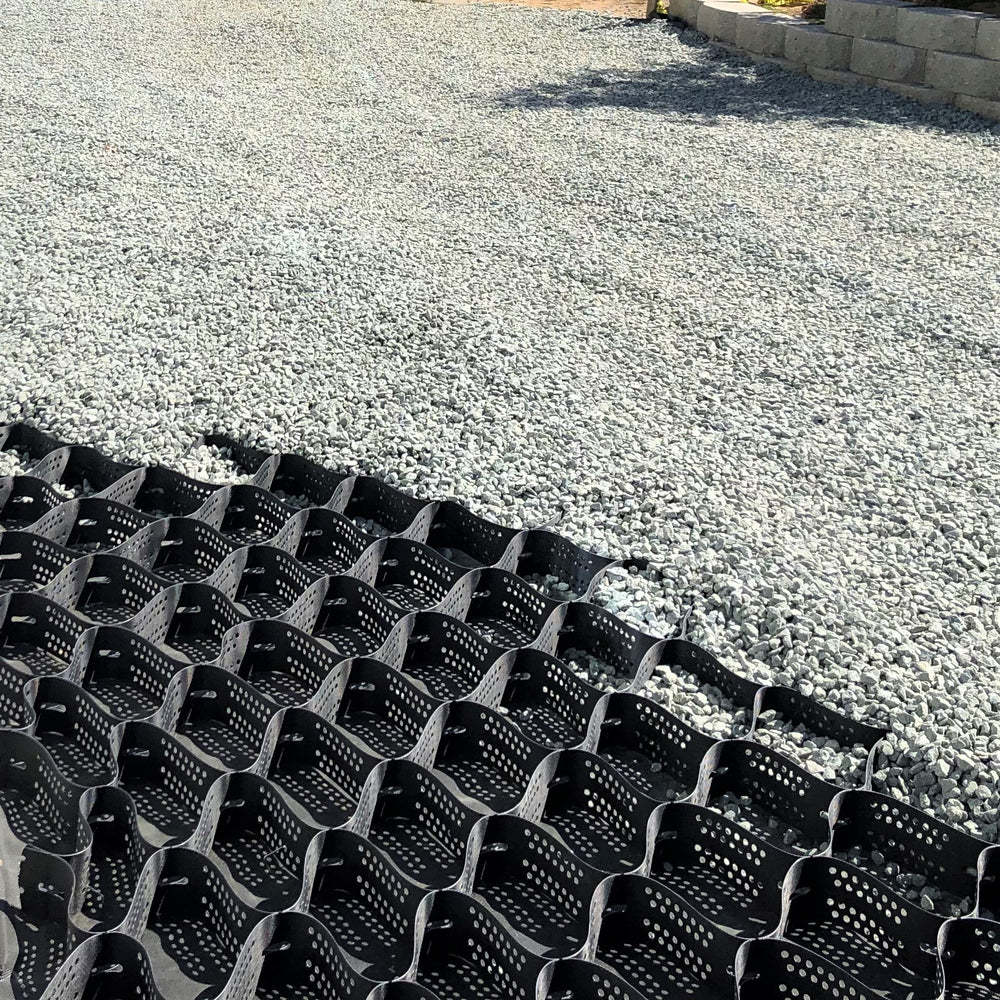

Key Advantages of Geocells for Railway Subgrade Reinforcement

Geocells, a three-dimensional cellular confinement system, offer significant advantages for stabilizing and reinforcing railway subgrades. Their unique structure provides a robust solution for challenging soil conditions.

Application of Geotextiles in Tunnel Anti-Seepage Construction

Geotextiles are widely used in tunnel engineering for their excellent anti-seepage, filtration, and drainage properties.

Construction of Geocell Farms: A Step-by-Step Guide

Geocells (also known as cellular confinement systems) are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other polymeric materials. They are widely used in agriculture to improve soil stability, prevent erosion, and enhance crop growth by reinforcing the ground.