Geotextile Anti-Seepage Construction Technology

Release time:

Jan 09,2023

1. Introduction

Geotextile anti-seepage construction is a widely used technique in civil engineering, water conservancy, environmental protection, and other fields to prevent water leakage and soil erosion. Geotextiles, as a permeable material, are often combined with impermeable membranes (such as HDPE geomembranes) to form composite anti-seepage systems, offering advantages such as high strength, corrosion resistance, and durability.

2. Material Selection

Geotextile: Typically made of polyester or polypropylene, it functions as a protective and drainage layer.

Impermeable Membrane: Commonly used materials include HDPE (high-density polyethylene), LDPE (low-density polyethylene), and PVC (polyvinyl chloride).

Ancillary Materials: Includes adhesives, welding rods, and anchoring fixtures to ensure system integrity.

3. Construction Process

(1) Base Preparation

Clear debris, rocks, and sharp objects from the construction area.

Level and compact the foundation to ensure a smooth surface without significant unevenness.

For slopes, maintain a stable gradient (typically ≤ 1:2.5).

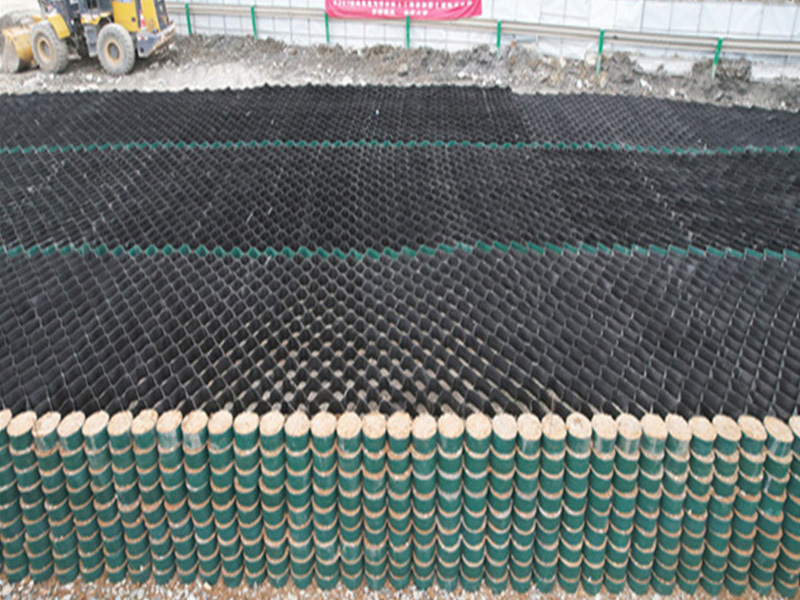

(2) Geotextile Laying

Roll out the geotextile along the slope or base direction, avoiding excessive tension to prevent deformation.

Overlap adjacent geotextile sheets by 10–15 cm, securing them with stitching or hot-air welding.

(3) Impermeable Membrane Installation

Lay the impermeable membrane over the geotextile, ensuring tight contact without wrinkles.

Overlap membrane edges by ≥10 cm and use dual-track hot wedge welding for sealing.

Conduct leak detection (e.g., vacuum or spark testing) post-welding.

(4) Protective Layer Construction

Cover the impermeable layer with a secondary geotextile or soil layer (≥30 cm thick) to prevent mechanical damage.

For slopes, use gabions or concrete blocks for additional reinforcement.

4. Quality Control

Material Inspection: Verify product certifications and conduct on-site sampling tests.

Welding Quality: Check seam strength and airtightness regularly.

Post-Construction Monitoring: Regularly inspect for leaks or damage.

5. Applications

Landfills: Prevents leachate contamination.

Water Reservoirs & Canals: Enhances water retention.

Mining & Industrial Sites: Controls seepage of harmful liquids.

6. Conclusion

Geotextile anti-seepage systems provide reliable, cost-effective solutions for seepage control. Proper material selection, meticulous construction, and strict quality control are essential for long-term performance.

This article outlines key steps and considerations in geotextile anti-seepage construction. Adjustments may be needed based on specific project requirements.

Next

Next

News

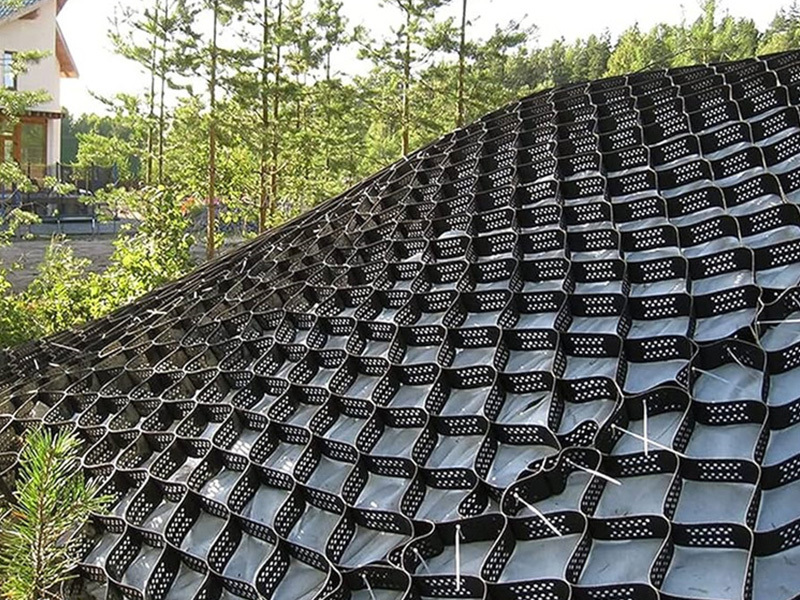

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection