Geotextile Applications in Highway Construction: Comprehensive Technical Guide

Release time:

Apr 19,2023

Geotextile Applications in Highway Construction: Comprehensive Technical Guide

1. Introduction

Geotextiles have become indispensable materials in modern highway engineering, offering multifunctional solutions for separation, filtration, drainage, and reinforcement. This technical guide details the systematic application of geotextiles in pavement systems, embankments, and drainage structures.

2. Material Specifications & Selection Criteria

2.1 Geotextile Types

Woven Geotextiles: High-tensile strength (20-100kN/m) for reinforcement

Non-woven Geotextiles: (100-500g/m²) for separation/filtration

Composite Geotextiles: Combined with geomembranes or drainage cores

2.2 Performance Parameters

Mechanical Properties:

Grab tensile strength: ≥800N (ASTM D4632)

Puncture resistance: ≥400N (ASTM D4833)

Trapezoidal tear strength: ≥250N (ASTM D4533)

Hydraulic Properties:

Permittivity: 0.01-2.0 sec⁻¹

Apparent opening size: 0.07-0.6mm (AOS O₉₀)

3. Key Functional Applications

3.1 Separation Layer in Pavement Systems

Installation Between:

Subgrade and aggregate base course

Old and new pavement layers

Performance Benefits:

Prevents intermixing of dissimilar materials

Reduces aggregate penetration into subgrade

Maintains design layer thickness

3.2 Embankment Reinforcement

Construction Techniques:

Basal reinforcement over soft soils

Wrap-around facing for steep slopes

Layered installation with geogrids

Design Considerations:

Required tensile strength calculation

Creep reduction factors

Interface friction coefficients

3.3 Drainage Systems

Edge Drain Applications:

Perforated pipe wrapping

French drain construction

Capillary Breaks:

Frost protection layers

Expansive soil treatment

4. Construction Methodology

4.1 Site Preparation

Subgrade Treatment:

Compaction to 95% Standard Proctor

Removal of sharp protrusions >10mm

Moisture content optimization

4.2 Geotextile Installation

Deployment Protocol:

Unrolling along traffic direction

Minimum 300mm side overlaps

600mm end overlaps

Anchoring Systems:

U-shaped pins at 1m spacing

Ballast placement (temporary)

Trench anchoring at edges

Seaming Techniques:

Sewn seams (Type SSa-1 per ASTM D4884)

Thermal bonding for nonwovens

Chemical adhesives for repairs

4.3 Overlay Construction

Aggregate Placement:

Dump-and-spread method prohibited

End-dumping with gradual forward movement

Minimum 150mm initial lift thickness

Compaction Control:

Vibratory rollers (initial pass <4km/h)

Progressive compaction sequencing

5. Quality Assurance Program

5.1 Material Certification

Factory Production Control:

Lot acceptance testing

Certification of compliance

On-site Verification:

Roll identification checking

Visual defect inspection

5.2 Field Testing

Seam Strength Testing:

1 test per 500m² (min. 80% parent material strength)

Placement Verification:

Overlap measurements

Wrinkle assessment (<25mm height)

6. Performance Monitoring

6.1 Structural Health Indicators

Rut Depth Measurement:

Laser profiling comparison

Cross-slope verification

Deflection Testing:

Falling Weight Deflectometer surveys

Backcalculation analysis

6.2 Hydraulic Performance

Drainage Capacity:

In-situ permeability tests

Flow rate monitoring

Clogging Potential:

Long-term permittivity testing

Gradient ratio analysis

7. Case Studies

7.1 Heavy Haul Road Construction

Project Data:

8km access road (Minnesota taconite mine)

600kN axle loads

Solution:

Woven geotextile (120kN/m)

40% reduction in base course thickness

7.2 Coastal Highway Rehabilitation

Challenge:

Tidal zone soft soil conditions

Implementation:

Composite geotextile-sand mattress

60% increase in embankment stability

8. Maintenance & Rehabilitation

8.1 Inspection Protocol

Annual Surveys:

Edge condition assessment

Sediment accumulation checks

Post-Event Inspections:

Flood damage evaluation

Heavy storm impact analysis

8.2 Repair Techniques

Patching Methods:

Heat-bonded overlays

Chemical fusion repairs

System Replacement:

Full-width panel installation

Edge transition detailing

9. Emerging Technologies

Smart Geotextiles:

Fiber optic strain sensing

Moisture detection fabrics

Sustainable Variants:

Recycled polyester products

Biodegradable temporary geotextiles

10. Conclusion

Geotextile applications in highway construction provide engineered solutions that significantly enhance pavement performance while reducing life-cycle costs. When properly specified and installed, geotextiles demonstrate:

Documented Benefits:

30-50% extension of service life

20-40% material cost savings

60% reduction in maintenance frequency

Improved sustainability through resource optimization

For optimal performance, engineers should consider site-specific conditions including:

Traffic loading spectra

Climatic factors

Subgrade soil characteristics

Construction methodology constraints

The integration of advanced monitoring technologies with geotextile systems is transforming highway asset management, enabling predictive maintenance strategies based on real-time performance data.

Next

News

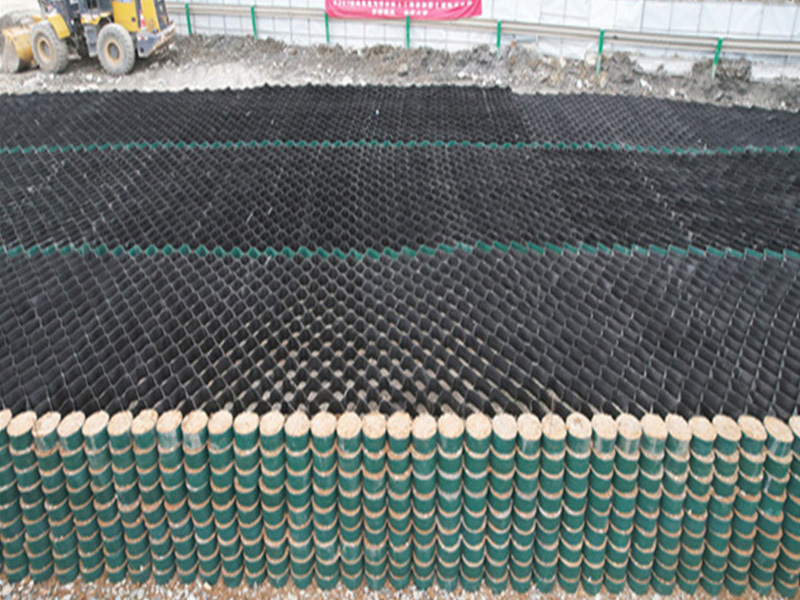

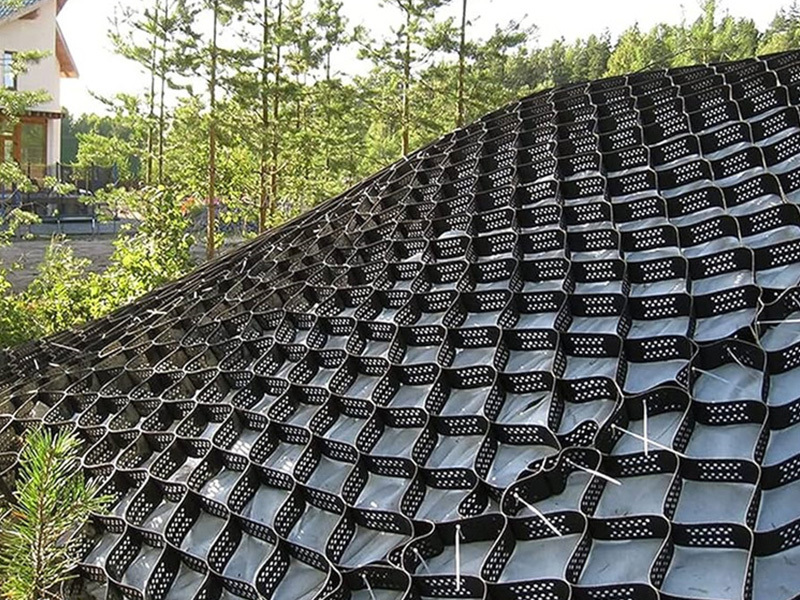

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection

HDPE Geomembrane Waterproofing Construction for Reservoirs

Waterproofing Construction for Reservoirs