Geocell Slope Stabilization: Construction Techniques and Engineering Applications

Release time:

May 10,2023

1. Introduction

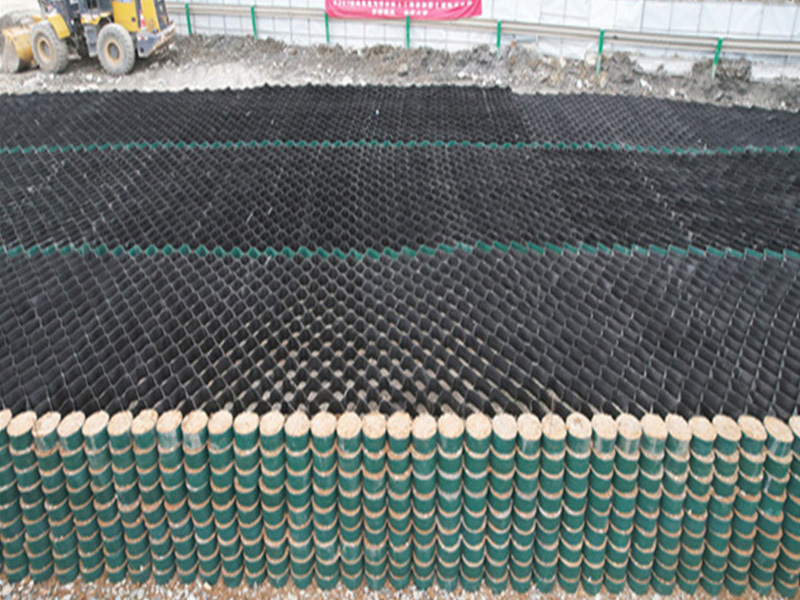

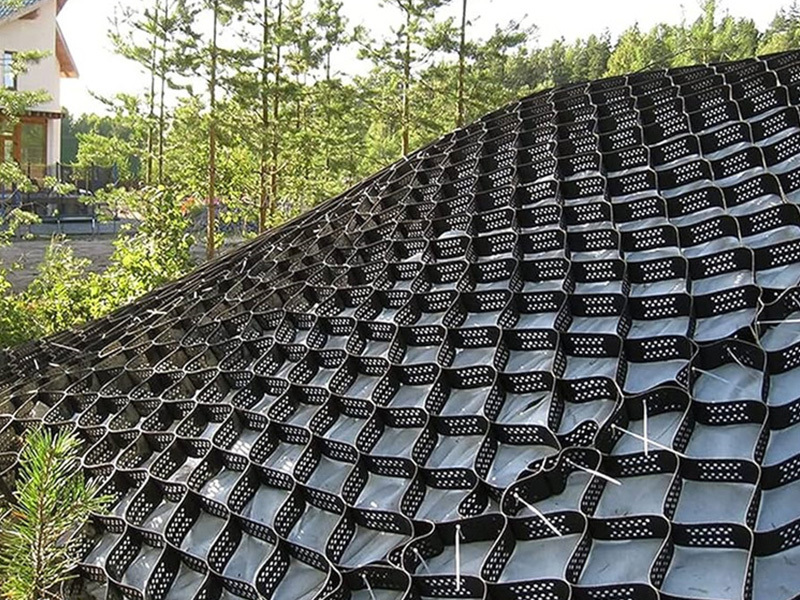

Geocell slope stabilization systems represent an advanced soil confinement technology for erosion control and hillside reinforcement. These three-dimensional cellular structures, typically manufactured from high-density polyethylene (HDPE) or novel polymer alloys, provide exceptional slope stability through mechanical interlock and lateral confinement of infill materials.

2. System Components and Material Specifications

2.1 Geocell Characteristics

Material Composition:

UV-stabilized HDPE (≥97% purity)

Perforated designs (6-20mm apertures) for drainage

Carbon-black additive for extended service life

Dimensional Parameters:

Cell height: 100-300mm (standard range)

Cell diameter: 200-400mm

Sheet dimensions: 4m×25m (unexpanded)

2.2 Ancillary Materials

Reinforcement Elements:

Geogrid underlayers (for high shear slopes)

Anchor spikes (600-900mm length)

Infill Options:

Aggregate (25-50mm crushed stone)

Vegetated soil (engineered growth medium)

Flowable fill (for structural applications)

3. Engineering Design Considerations

3.1 Slope Stability Analysis

Geotechnical Evaluation:

Shear strength parameters (c, φ)

Groundwater conditions

Seismic activity factors

Design Calculations:

Global stability analysis (Bishop's method)

Bearing capacity verification

Hydraulic conductivity requirements

3.2 Configuration Options

Surface Protection: Single-layer deployment

Structural Reinforcement: Multi-tiered systems with benching

Hybrid Solutions: Geocell-geogrid composites

4. Construction Methodology

4.1 Site Preparation

Slope Grading:

Cut-and-fill operations to ≤1:1.5 gradient

Subgrade compaction to 92% Proctor density

Berm construction at 10m vertical intervals

Surface Treatment:

Geotextile installation (200g/m² minimum)

Hydraulic erosion control measures

4.2 Geocell Installation

Deployment Protocol:

Unfolding perpendicular to slope direction

Expansion to design height (mechanical stretchers)

Anchor placement: 1m grid pattern

Connection Systems:

J-hook connectors (galvanized steel)

Ultrasonic welding (for critical applications)

Zip-tie fasteners (temporary fixation)

Infill Placement:

Layered compaction (150mm lifts)

Vibratory plate compactors (≥90% relative density)

Surface grading for drainage

4.3 Vegetation Establishment

Hydroseeding: Tackified fiber matrix

Erosion Control Blankets: Biodegradable varieties

Root Reinforcement: Soil stabilization additives

5. Quality Control Measures

5.1 Material Testing

Tensile Strength: ≥23MPa (machine direction)

Creep Resistance: ≤2% @ 20°C/10 years

Environmental Stress Crack Resistance: ≥500hrs

5.2 Field Verification

Anchor Pullout Tests: ≥1.5kN resistance

Infill Density Testing: Nuclear density gauge

Surface Runoff Monitoring: 10-year storm simulation

6. Performance Metrics

Erosion Reduction: ≥85% vs. unprotected slopes

Load Distribution: 3:1 stress reduction ratio

Service Life: 50+ years (UV-protected applications)

Deformation Limits: ≤3% under design loads

7. Special Applications

7.1 High-Risk Slopes

Landslide Remediation: Deep-seated failure repair

Mine Reclamation: Acid rock drainage control

Earthquake Zones: Flexible seismic performance

7.2 Transportation Infrastructure

Cut Slope Protection: Adjacent to highways

Embankment Reinforcement: Bridge approaches

Railway Stabilization: Vibration dampening

8. Case Studies

Hong Kong Hillside Stabilization: 45° slopes in tropical climate

Colorado Mine Restoration: 3-tier geocell system

Alpine Road Project: Snow load resistance verification

9. Maintenance Protocol

Annual Inspections: Post-monsoon/spring thaw

Repair Techniques:

Spot infill replacement

Anchor reinforcement

Surface vegetation renewal

10. Emerging Technologies

Smart Geocells: Strain monitoring sensors

Recycled Material Variants: Sustainable polymers

Self-vegetating Systems: Embedded seed technology

11. Conclusion

Geocell slope stabilization systems provide engineers with a versatile, cost-effective solution for hillside construction challenges. Their unique combination of mechanical reinforcement and ecological compatibility makes them particularly suitable for sustainable infrastructure development. When properly designed and installed, geocell structures demonstrate superior performance compared to conventional retaining systems, with typical cost savings of 30-50% and significantly reduced environmental impact.

Key Advantages:

Immediate load-bearing capacity

Enhanced surface drainage characteristics

Progressive failure mode (vs catastrophic collapse)

Aesthetically favorable vegetative cover

For critical projects, the integration of real-time monitoring systems with geocell networks enables predictive maintenance and early warning of potential instability, representing the next frontier in slope stabilization technology.

News

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection

HDPE Geomembrane Waterproofing Construction for Reservoirs

Waterproofing Construction for Reservoirs