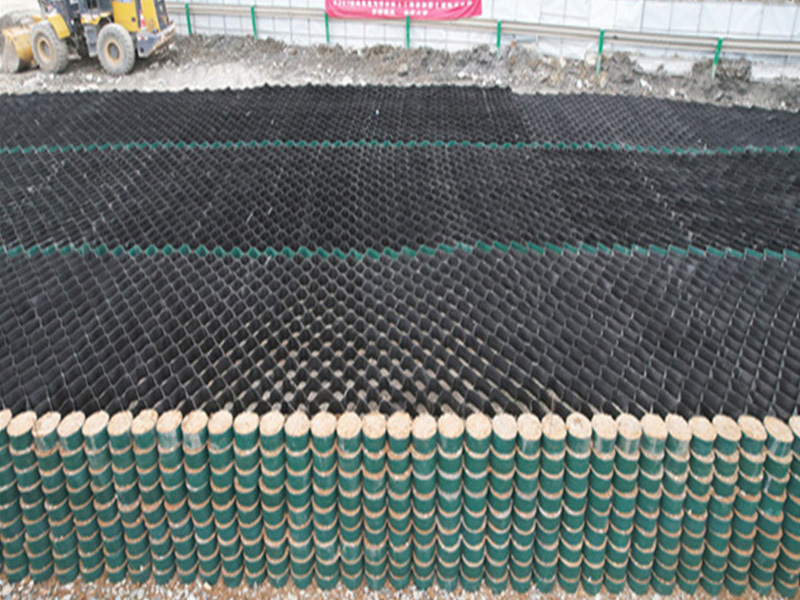

Geotextile Dam Anti-Seepage Construction

Release time:

Nov 21,2023

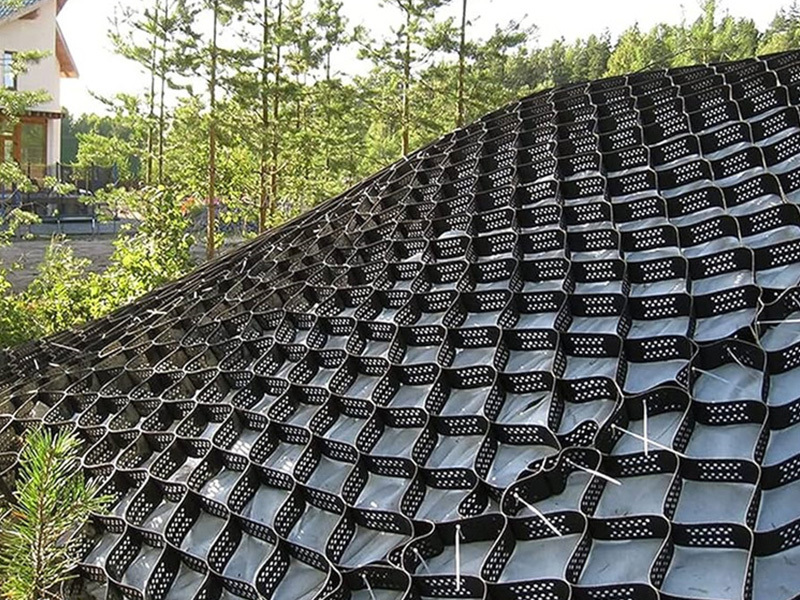

Key Steps in Geocell Retaining Wall Construction

Key Construction Steps:

Base Preparation – Clean and level the dam surface, removing sharp objects and loose soil.

Geotextile Laying – Roll out the geotextile (geomembrane or composite liner) with overlaps (typically 30–50 cm) to ensure continuity.

Seam Welding/Sealing – Use thermal fusion, adhesive, or solvent welding to seal overlaps for a watertight barrier.

Anchoring – Secure edges in trenches or with ballast to prevent displacement.

Protective Layer – Cover with a layer of soil, gravel, or concrete to shield against UV and mechanical damage.

Quality Inspection – Conduct leak detection (e.g., electrical or vacuum testing) and repair defects.

Materials Used:

Geomembrane (HDPE, LDPE, or PVC) for impermeability.

Nonwoven Geotextile as a cushion/protective layer.

Drainage Geocomposites (optional) to relieve water pressure.

Advantages:

High Impermeability – Prevents water leakage effectively.

Durability – Resists chemical corrosion and punctures.

Cost-Efficiency – Lower labor and material costs vs. traditional methods.

Applications:

Embankment dams, reservoirs, tailings ponds, and canal linings.

Need further details on standards (e.g., ASTM) or design considerations?

Next

Next

News

Geocell Technology for Slope Protection: Mechanisms and Applications

Geocell Technology for Slope Protection

HDPE Geomembrane Waterproofing Construction for Reservoirs

Waterproofing Construction for Reservoirs