Product Series

Contact Us

Tel: +86-538-6110571

Fax: +86-538-8411002

E-mail: sales@rhgeos.com

Whatspp: 8615866038408

Address: NO.3566 Longquan Road, Tai'an Hi-tech Zone, Shandong Province, China

Product Description

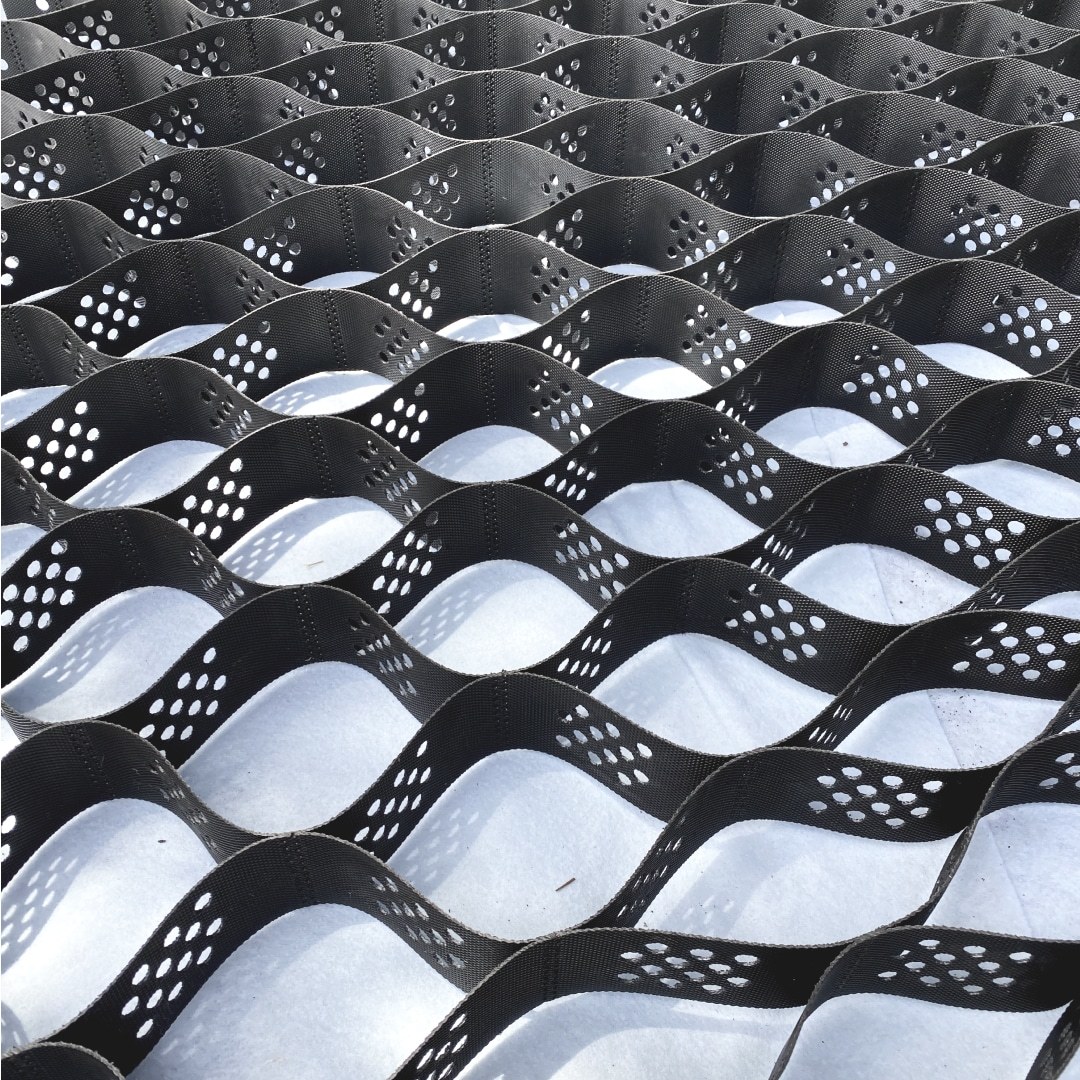

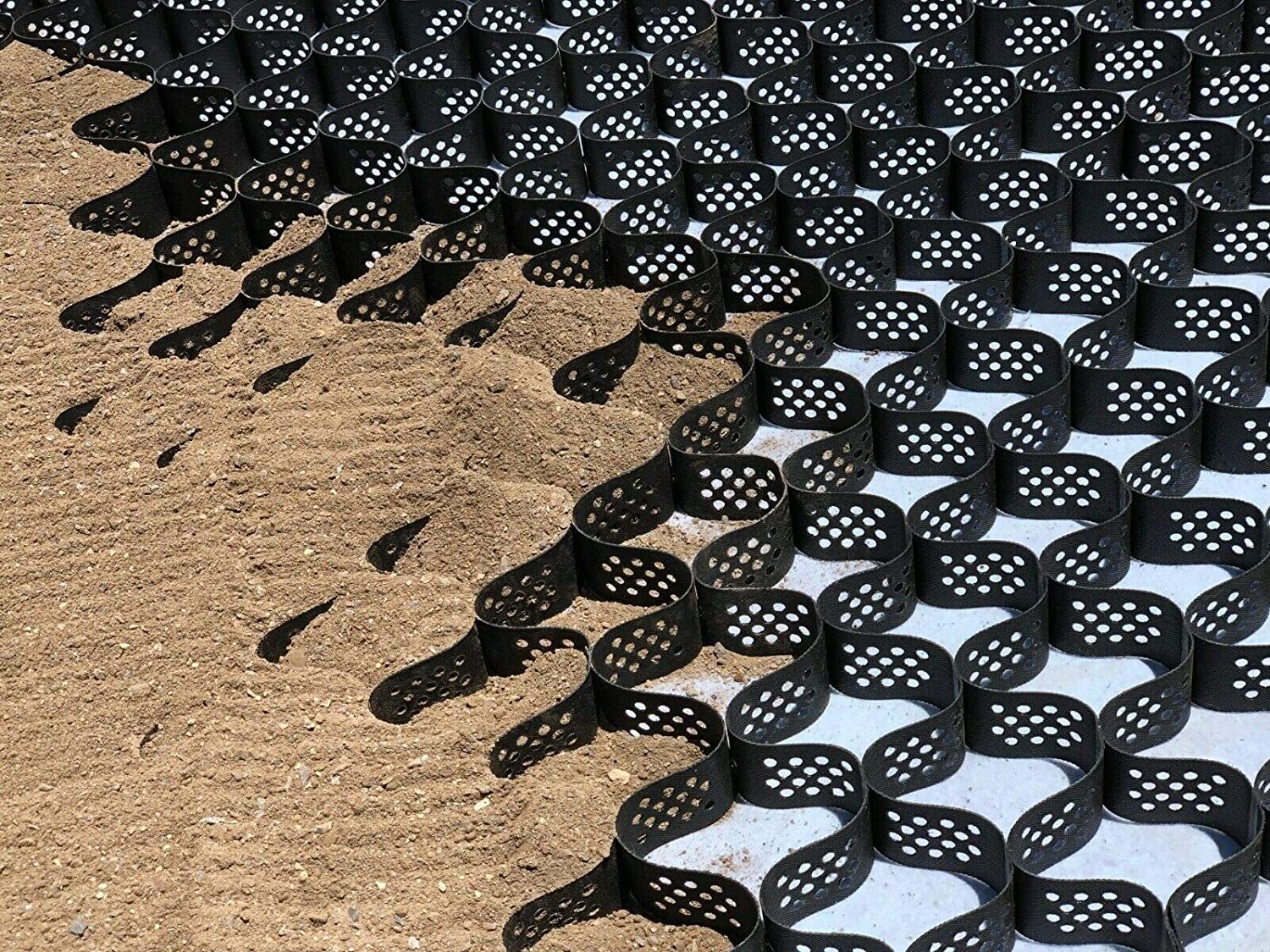

Geocells, a versatile class of geosynthetics, have become an invaluable tool in modern golf course construction and renovation. These three-dimensional, honeycomb-like structures, typically made from high-density polyethylene (HDPE), provide superior soil confinement and erosion control. Their application is particularly beneficial for stabilizing slopes, reinforcing turf, and creating sustainable playing surfaces. This article outlines the key steps and considerations for the successful installation of geocells on a golf course.

| Model Example | Weld Distance (mm) | Cell Depth (mm) | Sheet Thickness (mm) | Material | Typical Expanded Dimensions (approx.) | Key Applications |

|---|---|---|---|---|---|---|

| Model Example | Weld Distance (mm) | Cell Depth (mm) | Sheet Thickness (mm) | Material | Typical Expanded Dimensions (approx.) | Key Applications |

| GC-H50-100 | 400 | 50 | 1.0 | HDPE | 4m x 12.5m | Lightweight Erosion Control, Turf Reinforcement |

| GC-H100-150 | 400 | 100 | 1.5 | HDPE | 4m x 12.5m | Road Base, Railway Subgrade, Slope Protection |

| GC-H150-200 | 400 | 150 | 2.0 | HDPE | 4m x 12.5m | Heavy-Duty Load Support, Shoreline Protection |

| GC-H200-200 | 400 | 200 | 2.0 | HDPE | 4m x 12.5m | Very High Load Applications (e.g., steep slopes, deep soil confinement) |

| GC-P100-150 | 400 | 100 | 1.5 | PP |

1. Site Preparation

The foundation of any successful geocell installation is thorough site preparation.

Earthworks and Grading: The area must be graded to the desired final contour. This includes shaping slopes for fairways, tee boxes, or bunker faces. All vegetation, debris, and large rocks should be removed.

Subgrade Compaction: The underlying soil (subgrade) must be properly compacted to achieve a firm, stable base. A smooth-drum roller is commonly used. The goal is to create a uniform surface that can support the geocell and the overlying loads without significant settlement.

Geotextile Installation (Optional but Recommended): For most golf course applications, installing a non-woven geotextile fabric on the compacted subgrade is highly advisable. This fabric acts as a separator, preventing the infill material from mixing with the subsoil, and also provides additional drainage and reinforcement.

2. Geocell Placement and Expansion

Layout: The geocell panels are transported to the site in a folded, compact state. They are laid out flat along the prepared area according to the project design drawings.

Anchoring: The panels must be anchored securely at the top of a slope or along the perimeter to prevent down-slope creep during infilling. U-shaped rebar stakes or landscape anchors are typically driven through the cell seams and into the subgrade.

Expansion: Once anchored, the panels are expanded in the down-slope direction to their full three-dimensional height. The cells should be stretched taut to form a uniform honeycomb grid. Additional anchors are placed along the perimeter and within the field to maintain the geometry during construction.

3. Infilling the Cells

The choice of infill material is critical and depends on the specific application.

Material Selection:

For Grassed Areas (Tee Boxes, Fairways, Slopes): A free-draining, sandy loam or topsoil mix is ideal. It provides excellent growing medium for turfgrass while being effectively confined by the geocells.

For Cart Paths or High-Traffic Areas: A well-graded aggregate or crushed stone is used. The geocells confine the aggregate, creating a stable, permeable, and durable reinforced layer that resists rutting.

Infilling Technique: The infill material is placed from the top of the slope downward. It is crucial to use equipment that will not damage the geocells.

For Soil Infill: A low-ground-pressure bulldozer or a conveyor truck is preferred. The material should be poured evenly and then spread with a rake or a lightweight blade to ensure all cells are filled to capacity without overfilling the cell walls.

For Aggregate Infill: A small loader or a skid-steer can be used. The material is spread and then lightly compacted within the cells using a vibratory plate compactor.

4. Final Compaction and Turf Establishment

Compaction: After the cells are filled slightly above the top, a light pass with a vibratory roller or plate compactor ensures proper compaction of the infill. This step is more critical for aggregate infills but a light rolling can also help settle soil for turf establishment.

Seeding or Sodding: For vegetated applications, the final step is turf establishment. The confined surface can be hydroseeded, traditionally seeded, or covered with sod. The geocell grid provides an exceptional root reinforcement system, helping the turf establish a strong, interlocked mat that is highly resistant to erosion and wear from foot traffic and golf swings.

Key Applications on a Golf Course

Slope Stabilization on Fairways and Bunkers: Prevents soil erosion on steep grades, maintaining design integrity.

Tee Box and Green Apron Reinforcement: Reduces wear and tear from concentrated foot traffic and divots, providing a more stable and consistent playing surface.

Cart Path Bases: Creates a stable, yet permeable, base for paths, reducing mud and rutting, especially in environmentally sensitive areas.

Drainage Swales and Channels: Protects grass-lined channels from scour during heavy rainfall.

Conclusion

The use of geocells in golf course construction represents a fusion of engineering and agronomy. By following a meticulous process of site preparation, secure anchoring, and proper infilling, golf course architects and contractors can create landscapes that are not only aesthetically pleasing but also exceptionally durable and sustainable. The result is a superior playing surface that can withstand the elements and heavy use, ensuring the long-term health and playability of the course.

Packaging & Dispatch

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Recommended Products

Accreditation

FAQ

Q

Can we visit the factory?

A

We warmly welcome you to visit our company.

Q

How long does it take for the order to be shipped?

A

The delivery time and cycle may vary depending on warehousing, production, and order quantity. The specific time can be determined through communication.