Product Series

Contact Us

Tel: +86-538-6110571

Fax: +86-538-8411002

E-mail: sales@rhgeos.com

Whatspp: 8615866038408

Address: NO.3566 Longquan Road, Tai'an Hi-tech Zone, Shandong Province, China

Product Description

Introduction

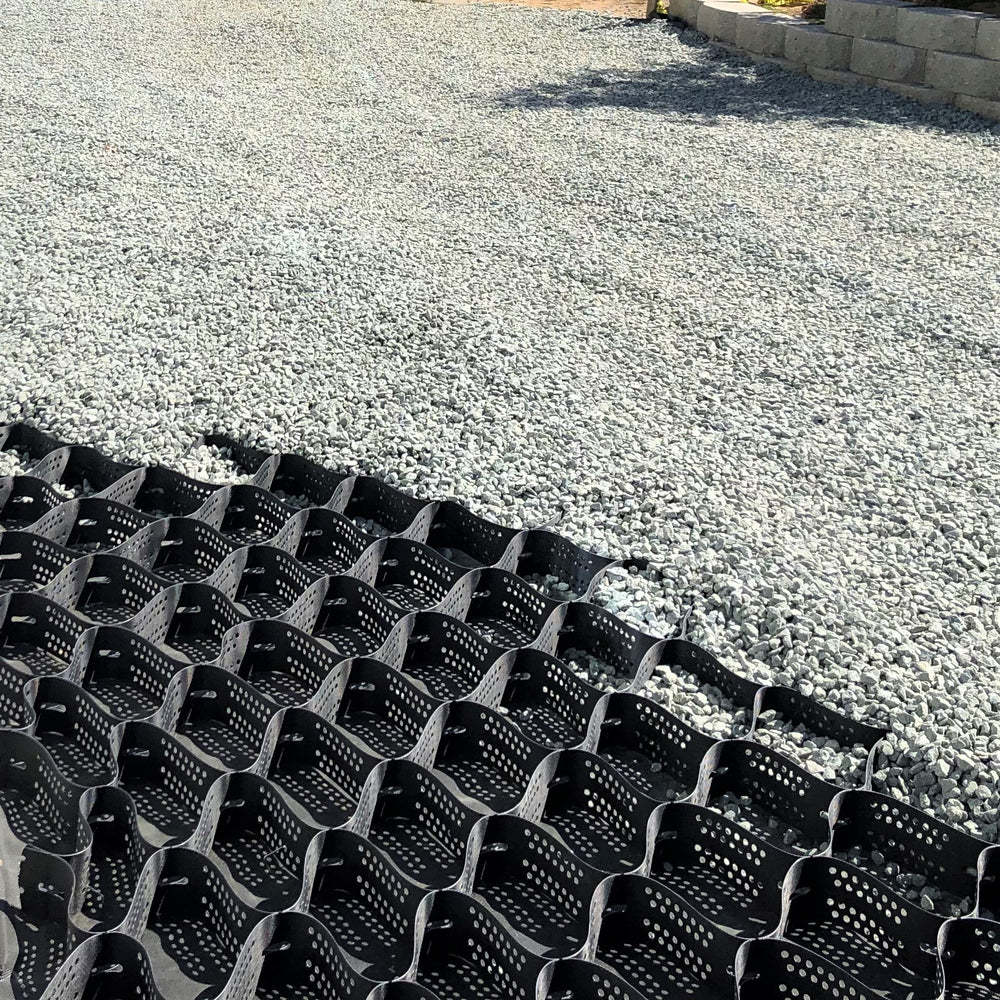

Geocells (also known as cellular confinement systems) are three-dimensional, honeycomb-like structures made from high-density polyethylene (HDPE) or other polymer alloys. When expanded and filled with soil, gravel, or other materials, they form a rigid and permeable mattress that provides exceptional erosion control, soil stabilization, and load support. This makes them ideal for a variety of challenging agricultural applications. This article details the key steps for the effective installation of geocells on a farm.

1. Planning and Site Assessment

Identify the Problem: Determine the primary purpose of the installation. Common farm uses include:

Erosion Control on Slopes: Preventing soil loss on ditch banks, pond embankments, or hilly pastures.

Heavy-Duty Access Roads: Creating stable, mud-free roads for tractors and trucks, even in wet conditions.

Livestock High-Traffic Areas: Reinforcing ground in feedlots, around water troughs, and gateways to prevent mud and potholes.

Channel Protection: Lining drainage ditches to prevent scour and maintain shape.

Material Selection: Choose the geocell's depth (cell height), weld spacing, and material strength based on the intended load and fill material. Deeper cells (e.g., 150-200mm) are used for higher loads and greater erosion control.

2. Site Preparation

Proper preparation is critical for long-term performance.

Clearing and Grading: Remove vegetation, rocks, and debris. The goal is a relatively smooth and compacted subgrade that follows the desired final contour.

Excavation (if necessary): For load support applications like roads, excavate to the required depth to accommodate the geocell and the infill material.

Subgrade Compaction: Compact the soil subgrade to provide a firm, stable foundation. This prevents uneven settling.

3. Geocell Installation Process

Layout and Orientation: Place the collapsed geocell panels on the prepared subgrade. Typically, the machine direction (direction of expansion) should run perpendicular to the slope or the direction of primary traffic for maximum resistance.

Expansion: Stake one end of the panel securely. Expand the panel fully along its length, ensuring all cells are opened to their full height and shape.

Anchoring: Secure the geocell to the subgrade using anchoring pins or J-hooks through the cell junctions around the perimeter and at regular intervals across the field. This prevents movement during the filling process.

4. Filling the Cells

Selecting Infill Material: The choice of fill is crucial. For erosion control, native soil or sand can be used. For high-load support, well-graded aggregate (crushed stone, gravel) is essential.

Filling Technique:

First Pass (~75% Full): Pour or blow fill material into the cells. Use a loader or a backhoe to spread the material. Do not drag equipment over the unfilled or partially filled geocell, as this can damage it.

Compaction: Lightly compact the initial lift of infill within the cells. For soil, use a vibratory plate compactor. For aggregate, a roller may be used.

Second Pass (Overfilling): Continue filling the cells until the material is slightly mounded above the cell walls (~25-50mm). This allows for natural settlement and creates a fully interlocked layer.

Final Compaction: Perform a final compaction pass to achieve the desired density and create a monolithic, stable layer.

5. Final Steps and Vegetation (For Erosion Control)

Capping Layer (Optional): For roads, the filled geocell itself is often the wearing surface. For other applications, a thin layer of topsoil can be spread over the filled cells.

Revegetation: On slopes, the filled cells can be seeded and fertilized. The cell walls protect the seeds and soil from wash-off until vegetation is established, creating a permanent, reinforced root matrix.

Key Advantages on the Farm:

Superior Load Distribution: Converts vertical loads into horizontal stresses, creating a "snowshoe" effect that prevents rutting on weak subgrades.

Confinement: The cells confine the infill material, preventing lateral movement and displacement under load.

Permeability: Allows water to pass through freely, eliminating hydroplaning and reducing runoff.

Flexibility: Conforms to ground settlements and uneven terrain without losing structural integrity.

Conclusion

Geocells offer a durable, cost-effective, and engineered solution for some of the most persistent ground stabilization problems on the farm. By following a meticulous installation process—focusing on subgrade preparation, secure anchoring, and proper filling techniques—farmers can construct reinforced surfaces that withstand heavy equipment, eliminate mud, and control erosion for years to come, ultimately improving operational efficiency and environmental stewardship.

Packaging & Dispatch

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Recommended Products

Accreditation

FAQ

Q

Can we visit the factory?

A

We warmly welcome you to visit our company.

Q

How long does it take for the order to be shipped?

A

The delivery time and cycle may vary depending on warehousing, production, and order quantity. The specific time can be determined through communication.