Product Series

Contact Us

Tel: +86-538-6110571

Fax: +86-538-8411002

E-mail: sales@rhgeos.com

Whatspp: 8615866038408

Address: NO.3566 Longquan Road, Tai'an Hi-tech Zone, Shandong Province, China

Product Description

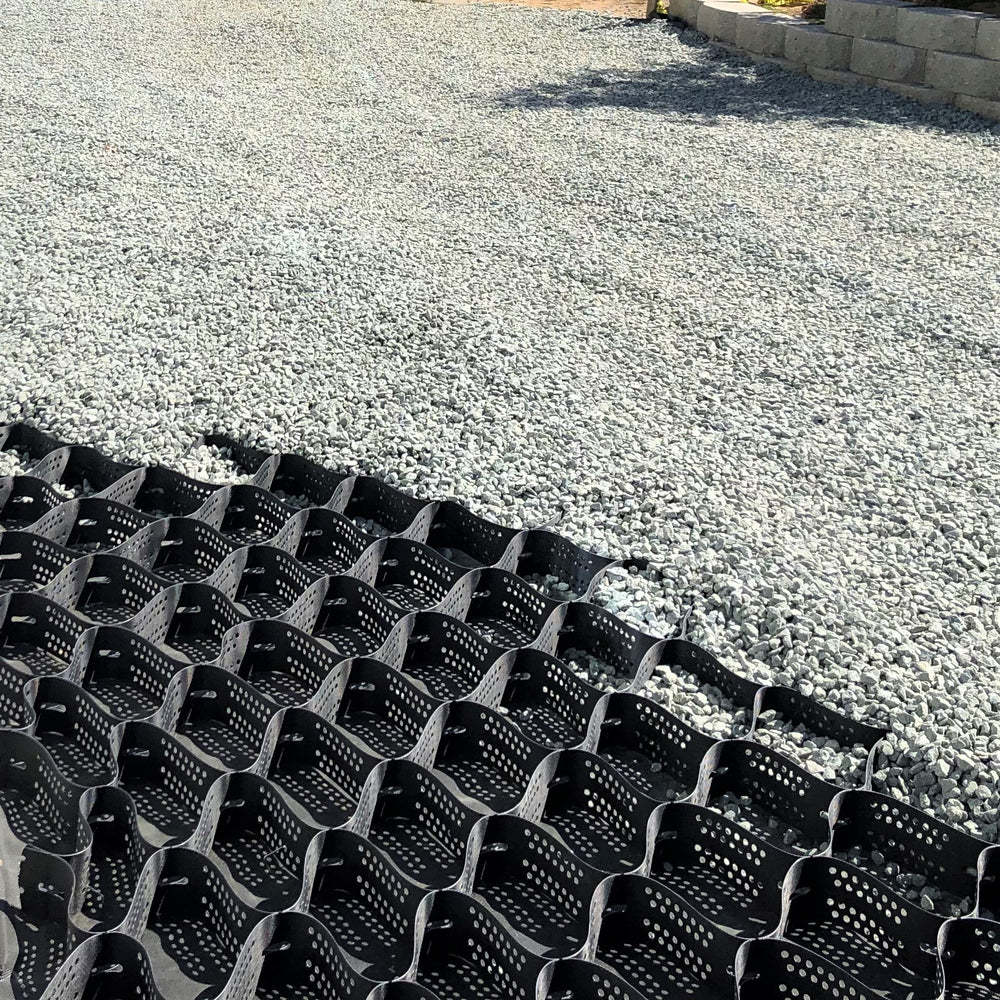

Geocells are three-dimensional cellular structures that can be filled with soil, gravel, or other materials to stabilize steep slopes and prevent erosion. They are made from high-density polyethylene (HDPE) and have an open cell structure that allows them to conform to the terrain.

Geocells are an innovative way to wall and confine soil, aggregate, and other fill materials. These three-dimensional cellular structures can expand during installation, forming flexible walls with interconnected strips to increase tensile strength, all while increasing compression due to environmental factors such as weathering. Prevents movement by holding it in place.

When the soil enclosed within a geocell is stressed, such as in load-bearing applications, lateral strains occur in the surrounding cell walls. Although the 3D zone of confinement reduces the lateral mobility of soil particles, the vertical loading on the confined infill creates significant lateral stress and resistance at the cell-soil interface.

Geocells are used in construction to reduce erosion, stabilize soils, protect waterways, and provide structural reinforcement for load bearing and earth retention.

Geocells were first developed in the early 1990s by he as a way to improve the stability of roads and bridges. They quickly became popular for their ability to stabilize soil and control erosion in steep ground. Geocells are currently used in a variety of applications, including road construction, landfills, mining operations, and green infrastructure projects.

Material Properties | unit |

|

|

|

| Tested Method |

Cell Depth | mm | 75 | 100 | 150 | 200 |

|

Polymer Density | g/cm3 | 0.935-0.965 | ASTM D 1505 | |||

Enviroment Stress Crack Resistance | Hours | >400 | ASTM D 5397 | |||

Enviroment Stress Crack Resistance | Hours | 6000 | ASTM D 1693 | |||

Carbon Black Content | % | 1.5%-2.0% | ASTM D 1603 | |||

Nominal Sheet Thickness Before Texturing | mm | 1.27-5%,+10% | ASTM D 5199 | |||

Nominal Sheet Thickness After Texturing | mm | 1.27-5%,+10% | ASTM D 5199 | |||

Strip Puncture Resistance | N | 450 | ASTM D 4833 | |||

Seam Peel Strength | N | 1065 | 1420 | 2130 | 2840 | EN ISO 13426-1B |

Seam Efficiency | % | GRI100 | GRI-GS13 | |||

Norminal Expanded Cell Size(width x length) | mm | 320x287,475x508 etc |

| |||

Norminal Expanded Panel Size(width x length) | m | 2.56x8.35,4.5x5.0,6.5x4.5,6.1x2.44 |

| |||

Packaging & Dispatch

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Recommended Products

Accreditation

FAQ

Q

Can we visit the factory?

A

We warmly welcome you to visit our company.

Q

How long does it take for the order to be shipped?

A

The delivery time and cycle may vary depending on warehousing, production, and order quantity. The specific time can be determined through communication.