Product Series

Contact Us

Tel: +86-538-6110571

Fax: +86-538-8411002

E-mail: sales@rhgeos.com

Whatspp: 8615866038408

Address: NO.3566 Longquan Road, Tai'an Hi-tech Zone, Shandong Province, China

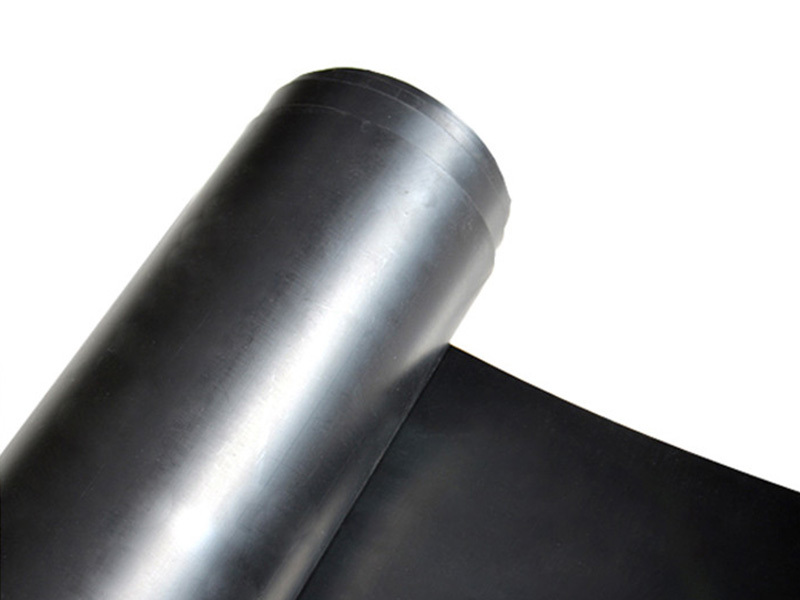

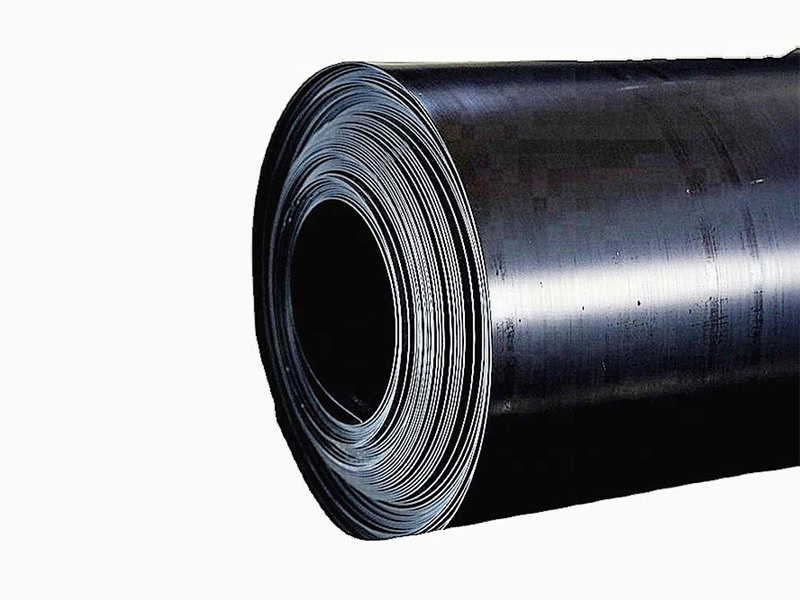

Geomembrane

HDPE Geomembrane is made of finest quality high density polyethylene (HDPE) with specially formulated, virgin polyethylene resin, combined with specified quantity carbon black, antioxidant, anti-aging agent and UV resistance components, which makes our smooth geomembrane HDPE Geomembrane with excellent resistance to UV radiation and is suitable for exposed conditions.

Keyword:

Product Description

HDPE Geomembrane is made of finest quality high density polyethylene (HDPE) with specially formulated, virgin polyethylene resin, combined with specified quantity carbon black, antioxidant, anti-aging agent and UV resistance components, which makes our smooth geomembrane HDPE Geomembrane with excellent resistance to UV radiation and is suitable for exposed conditions.

Thickness: 0.2mm, 0.3mm, 0.5mm, 0.75mm,1.0mm,1.5mm,2.0mm

Width: 4m, 5m, 5.8m, 6.0m, 7m, 8m

Length(per roll): 50m 100m 200m 400m

Product Parameters

|

Test |

Unit |

Standard |

Test Frequency |

RH75 |

RH10 |

RH15 |

RH20 |

RH30 |

|

|

Mechanical Properties |

Thickness |

mm |

D5199 |

per roll |

0.75 |

1.00 |

1.50 |

2.00 |

3.00 |

|

Density |

g/cc |

D1505/D792 |

90,000 kg |

0.94 |

|||||

|

Tensile Properties |

|

D 6693 |

|

|

|

|

|

|

|

|

· yield strength |

kN/m |

Type IV |

9,000 kg |

11 |

15 |

22 |

29 |

44 |

|

|

· break strength |

kN/m |

|

|

20 |

27 |

40 |

53 |

80 |

|

|

· yield elongation |

% |

|

|

12 |

12 |

12 |

12 |

12 |

|

|

· break elongation |

% |

|

|

700 |

700 |

700 |

700 |

700 |

|

|

Tear Resistance |

N |

D 1004 |

20,000 kg |

93 |

125 |

187 |

249 |

374 |

|

|

Puncture Resistance |

N |

D 4833 |

20,000 kg |

240 |

320 |

480 |

640 |

960 |

|

|

Stress Crack Resistance |

hr. |

D 5397 |

per GRI GM-10 |

500 hr. |

|||||

|

Carbon Black Content |

% |

D 4218 |

9,000 kg |

2.0-3.0% |

|||||

|

Reference Propertied |

Oxidative Induction Time |

min |

D 3895 |

90,000 kg |

100 min. |

||||

|

(a) Standard OIT |

D 5885 |

||||||||

|

(b) High Pressure OIT |

|

400 min. |

|||||||

|

Oven Aging at 85°C retained after 90 days |

% |

D 5721 |

per each |

|

|||||

|

(a) Standard OIT - % |

D 3895 |

formulation |

55% |

||||||

|

(b) High Pressure OIT - % |

D 5885 |

|

80% |

||||||

|

UV Resistance |

% |

|

per each |

|

|||||

|

High Pressure OIT - % retained after 1600 hrs |

D 5885 |

formulation |

50% |

||||||

|

Roll Size |

Roll Width |

m |

|

7/8 |

7/8 |

7/8 |

7/8 |

7 |

|

|

Roll Length |

m |

|

280 |

210 |

140 |

105 |

70 |

||

|

Size stability |

% |

2% |

|||||||

Packaging & Dispatch

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Recommended Products

Accreditation

FAQ

Q

Can we visit the factory?

A

We warmly welcome you to visit our company.

Q

How long does it take for the order to be shipped?

A

The delivery time and cycle may vary depending on warehousing, production, and order quantity. The specific time can be determined through communication.